Stray particles can be destructive in electronics production, so robots and the components that support them must minimize contamination. igus yesterday launched the Clean SCARA Cable Solution, which it said is made of high-performance plastics and works almost particle-free, according to ISO Class 2, even in high-speed applications.

Microscopic debris can ruin electronic components, semiconductors, and displays, noted igus. Machines moving at high speeds, such as SCARA robots that move along four axes in less than a second, can release particles from corrugated hoses and tubes.

“Finding a way to guide cables and hoses on a SCARA robot in a cleanroom is a science in itself,” said Matthias Meyer, head of the triflex and Robotics Business Unit at igus. “Fast movements are pure stress for the material, which releases unwelcome abrasion particles.”

For this reason, igus has added a cleanroom variant to its SCARA Cable Solution energy supply system, which it originally developed in 2020. The Rumford, R.I.-based company added that its Clean SCARA Cable Solution is stronger and more user-friendly than classic corrugated hoses.

“The new Clean SCARA Cable Solution is a cleanroom-compatible energy-supply system for high-speed applications – reliable, compact, easy to use, and quick to retrofit,” Meyer said in a release.

ISO Class 2 means minimal particles

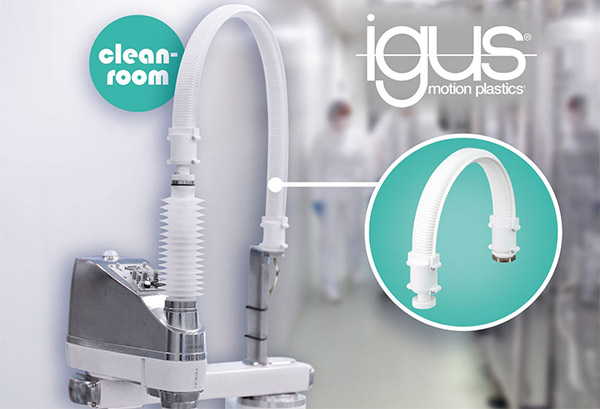

The core of the new cleanroom energy supply system is igus' e-skin Soft, a modular e-chain cable carrier that guides cables and hoses in an arc from the robot’s vertical arm to the end effector.

The company said its separable upper and lower shells can be combined to form a closed, dust-proof, water-resistant tube. This ensures that particles from the cables and hoses do not get into the surrounding air from the inside – even during the wildest movements, igus claimed.

“To reduce stress on the cables and increase their durability, we have provided a rotating mount for the connections to the fixed and moving ends of the energy supply system,” explained Meyer. “That is what is special about the energy-supply system. At the same time, the rotary bearings are designed to be almost particle-free, even during the most dynamic movements.”

The e-chain itself is also especially abrasion-resistant because of tribologically optimized high-performance plastic, said igus. The Fraunhofer Institute has confirmed this characteristic for an ISO (International Organization for Standardization) certification for cleanrooms.

The Clean SCARA Cable Solution has ISO Class 2, meaning that it is so abrasion-resistant that a maximum of 100 particles up to a size of 0.1 microns can be found in one cubic meter of air during operation. For comparison, a sheet of paper is 80 microns thick, or 800 times as thick as a particle.

igus presents Clean SCARA Cable Solution instead of corrugated hoses

igus said its new energy supply system offers an alternative to classic corrugated hoses, as well as two advantages in addition to cleanroom compatibility.

First, the thin corrugated hoses most often used with SCARA robots have hardly any inherent rigidity and are, therefore, susceptible to kinking. There is no bearing to absorb torsion, and the hoses can tear easily, the company observed.

“Unlike corrugated hoses, the Clean SCARA Cable Solution supports itself and has a unique rotary bearing,” Meyer said. “This makes it ideal for short unsupported lengths and highly dynamic applications. The oval chain geometry is especially advantageous when lateral forces are applied since it offers additional strength.”

Standard SCARA energy supply systems use static connections at the moving and fixed ends. This can lead to unnecessary fatigue on the corrugated tube at both points and increased wear on the cable package, said igus.

The Clean SCARA Cable Solution uses rotary connections at both ends, which all but eliminates mechanical stress on the energy supply system. “With the high speeds seen in SCARA applications, this improvement is a game-changer,” said igus.

The second advantage over the corrugated hose is that the zipper principle makes the Clean SCARA Cable Solution easy to open, enabling users to insert cables and hoses quickly. An optional interior separation provides additional protection that corrugated hoses cannot.

A customer can request the new cleanroom energy chain as a ready-to-connect complete system with igus chainflex cables. More than 900 highly flexible cables of IPA Class 1 are available, the company said.

Article topics

Email Sign Up