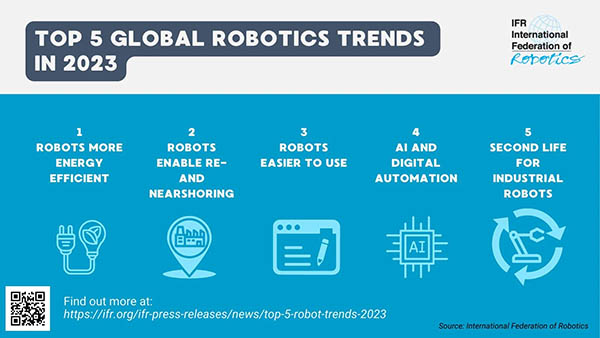

The International Federation of Robotics, or IFR, recently announced the five trends it sees shaping robotics and automation in 2023.

“Robots play a fundamental role in securing the changing demands of manufacturers around the world,” stated Marina Bill, president of the International Federation of Robotics. “New trends in robotics attract users from small enterprise to global OEMs.”

1. Energy efficiency

Energy efficiency is key to improve companies’ competitiveness amid rising energy costs. The adoption of robotics can help in many ways to lower energy consumption in manufacturing.

Compared with traditional assembly lines, considerable energy savings can be achieved through reduced heating. At the same time, robots work at high speed, thus increasing production rates so that manufacturing becomes more time- and energy-efficient.

Today’s robots are designed to consume less energy, which leads to lower operating costs. To meet sustainability targets for their production, companies use industrial robots equipped with energy-saving technology. For example, robot controls can convert kinetic energy into electricity and feed it back into the power grid.

This technology significantly reduces the energy required to run a robot. Another feature is the smart power-saving mode that controls the robot´s energy supply on-demand throughout the workday. Since industrial facilities need to monitor their energy consumption even today, such connected power sensors are likely to become industry-standard for robotics.

2. Reshoring

Resilience has become an important driver for reshoring in various industries. For instance, car manufacturers invest heavily in short supply lines to bring processes closer to their customers. These automakers use robots to produce powerful batteries cost-effectively and in large quantities to support their electric vehicle projects.

These investments make the shipment of heavy batteries redundant. This is important as more and more logistics companies refuse to ship batteries for safety reasons.

Relocating microchip production back to the U.S. and Europe is another reshoring trend. Since most industrial products nowadays require a semiconductor chip to function, it's crucial to bring their supply close to the customer. Robots play a vital role in chip manufacturing, as they live up to the extreme requirements of precision.

Specifically designed robots can automate the silicon wafer fabrication, take over cleaning and cleansing tasks, or test integrated circuits. Recent examples of reshoring are Intel's new chip factories in Ohio or the recently announced chip plant in the Saarland region of Germany run by chipmaker Wolfspeed and automotive supplier ZF.

3. Robots become easier to use

Robot programming has become easier and more accessible to non-experts. Providers of software-driven automation platforms support companies, letting users manage industrial robots with no prior programming experience.

Original equipment manufacturers work hand in hand with low-code or even no-code technology partners that allow users of all skill levels to program a robot.

The easy-to-use software paired with an intuitive user experience replaces extensive robotics programming and opens up new automation opportunities. Software start-ups are entering this market with specialized systems for the needs of small and midsized companies. For example, a traditional heavyweight industrial robot can be equipped with sensors and new software that allows collaborative operation.

This makes it easy for workers to adjust heavy machinery to different tasks. Companies will thus get the best of both worlds: robust and precise industrial robot hardware and state-of-the-art cobot software.

Easy-to-use programming interfaces, which allow customers to set up the robots themselves, also drive the emerging new segment of low-cost robotics.

Many new customers reacted to the pandemic in 2020 by trying out robotic solutions. Robot suppliers acknowledged this demand with easy setup and installation. This included pre-configured software to handle grippers, sensors, or controllers to support lower-cost robot deployment.

Such robots are often sold through Web shops and program routines for various applications are downloadable from an app store.

4. AI and digital automation

Propelled by advances in digital technologies, robot suppliers and systems integrators offer new applications and improve existing ones regarding speed and quality. Connected robots are transforming manufacturing.

Robots will increasingly operate as part of a connected digital ecosystem. Cloud computing, big data analytics, and 5G mobile networks provide the technological base for optimized performance. The 5G standard will enable fully digitalized production, making cables on the shop floor obsolete.

Artificial intelligence holds great potential for robotics, enabling a range of benefits in manufacturing. The main aim of using AI in robotics is to better manage variability and unpredictability in the external environment, either in real-time, or off-line.

Machine learning thus plays an increasing role in software that can provide benefits such as optimized processes, predictive maintenance, or vision-based gripping.

This technology is helping manufacturers, logistics providers, and retailers deal with frequently changing products, orders, and stock. The greater the variability and unpredictability of the environment, the more likely it is that AI algorithms will provide a cost-effective and fast solution.

For example this can help manufacturers or wholesalers dealing with millions of different products that change on a regular basis. AI is also useful in environments in which mobile robots need to distinguish between the objects or people they encounter and respond differently.

5. Second life for industrial robots

Since an industrial robot has a service life of up to 30 years, new tech equipment is a great opportunity to give old robots a “second life.” Industrial robot manufacturers such as ABB, FANUC, KUKA, and Yaskawa run specialized repair centers close to their customers to refurbish or upgrade used units in a resource-efficient way.

This prepare-to-repair strategy for robot manufacturers and their customers also saves costs and resources.

Article topics

Email Sign Up