Smart International, an authorized global brand licensee of 3D printing for Kodak, announces that KODAK 3D Printing will be expanding its range of materials to include Acrylic and Nylon 6/66/12, as well as launching a new accessory line to enable users of the KODAK Portrait 3D printer to expand on the materials it can print with.

Acrylic, a new filament designed by KODAK 3D Printing, combines polycarbonate properties that offer rigidity and are light conductive, while also being easy to print. It is suited to optical applications as the material conducts light, allowing for the 3D printing of interesting prototypes or for pieces requiring high transparency. In addition, the new Acrylic is low friction and can withstand high temperatures. Due to its low friction coefficient, it works with moveable parts.

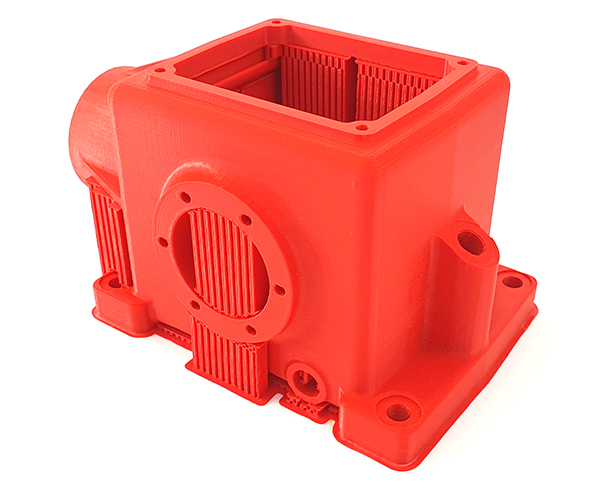

Nylon 6/66/12 has also been introduced, as strong as traditional Nylon, but with greater flexibility, according to Smart International. It is low warping and allows for better printing of fine details and overhangs. Used in conjunction with the KODAK Portrait 3D Printer, which has been designed specifically to print high-temperature engineering materials, with a fully enclosed chamber and robust all-steel structure, it allows for less warp and more successful prints, the company notes. Nylon 6/66/12 is suitable for parts that need to be strong with tensile resistance, or strong parts with fine details.

In addition to these two materials, KODAK 3D Printing is also launching a new range of accessories to complement the KODAK Portrait and to give even more options with its dual extrusion system. First to be available are two mirrored E3D hotends, one all-metal and one PTFE, which will enable users to replace one of the existing hotends so they can use 2 all-metals or 2 PTFE on the same machine. This will enable dual material prints using two high-temperature or two low-temperature materials, and also two-color combinations.

“We are laser focused on our users. Every new material and accessory we develop is application driven, aimed at solving engineering problems with parts capable of withstanding a wider and wider range of resistances and industry needs,” says Roberto Gawianski, CEO of Smart International. “The market demand for 3D Printing is ever-evolving, and KODAK 3D Printing aims to be a forerunner in bringing new innovations to life.”

Sources: Press materials received from the company and additional information gleaned from the company’s website.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up