MEMPHIS—As more robots from multiple vendors enter warehouses and other facilities, the need for them to work together becomes increasingly important for operators to realize the benefits of automation. Most of the discussions around interoperability have been theoretical—until now. Yesterday at the FedEx DART research and development center here, Vecna Robotics, Waypoint Robotics, and WiBotic successfully demonstrated MassRobotics' new standard for communications.

The demonstration was part of the Autonomous Mobile Robot (AMR) and Logistics Conference held by the Association for Advancing Automation (A3). While several organizations have recognized the need for interoperability among AMRs, yesterday's demonstration was the first time real-world systems used a common interface to report their locations.

“This is the very first level of capability,” said Daniel Theobald, founder and chief innovation officer of Vecna Robotics. He is also co-founder of MassRobotics, a consortium devoted to growing the Massachusetts robotics ecosystem. MassRobotics published its interoperability standard in May.

“We've seen industries and small companies buying robots struggle with interoperability,” said Ben Waters, co-founder and CEO of WiBotic. “It makes it harder for everyone to scale up.”

Robots can play well together

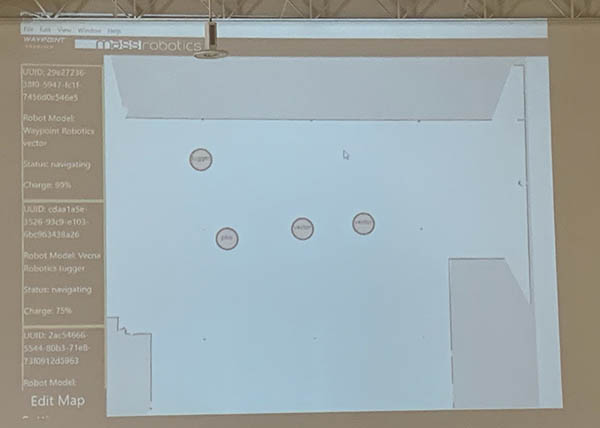

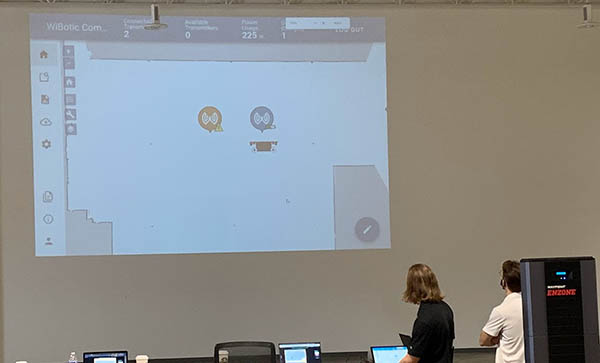

In the demonstration, a Vecna tugger, a Vector mobile robot and a MAV3K heavy-duty AMR from Waypoint, and two WiBotic wireless chargers all reported their relative locations. The results were displayed on a shared map.

“We've been working on this standard for more than a year,” Theobald told Robotics 24/7. “The actual implementation took 20 hours, and most of our challenges were with local networks.”

“Funny story—I made one mistake,” he recalled. “I didn't explain the interoperability portion of this demonstration, so the tugger was just prepared to run loops. The team had to drop in the code once we were here. It does show how easy it is to communicate if the willpower exists.”

“We tested the code and transport mechanisms and then tried things out,” said Jason Walker, CEO of Waypoint Robotics. “InOrbit even has ROS code with the standard baked in. We wanted to bring to robotics development what agile [methodology] does—rapid iterations versus waiting a year for perfection in the waterfall approach.”

InOrbit recently joined MassRobotics' standard effort. Its CEO, Florian Pestoni, is also co-founder of the Robot Operations Group (ROG), an industry community dedicated to advancing robot operations, or RobOps, best practices. ROG had its latest meeting at the A3 AMR & Logistics Conference.

Making mapping work

How does shared mapping work? “Each robot makes its own map, but they use a shared coordinate system,” replied Walker. “It's like hiking with GIS—we use common reference points.”

“There was a lot of debate, but users like FedEx have expressed strong interest in indoor and outdoor standards,” Theobald said. “It's basically GPS, which is different from the AGV [automated guided vehicle] world, where the robots precisely follow lines. That's not the way the real world works—it's less about the path than flexibly following goals. A lift truck or cleaning robot can navigate around people.”

The MassRobotics standard uses the WebSocket API (application programming interface). In yesterday's demonstration, the display consisted of a Vecna map with Waypoint and WiBotic information published to it.

More status reports to come

“The MassRobotics standard makes it easier for the ecosystem to adopt multifleet plug-and-play operations,” said Theobald. “The most common feedback we've had is that it takes a couple of hours [in comparison with the time it would take to create communications protocols from scratch].”

“Floor space and other shared resources are also part of this—it's not just about AMRs avoiding collision,” he added. “One of the most pressing things that we're likely to tackle next is charging. Most robots have proprietary chargers.”

“It's often overlooked, but imagine the scale of hundreds or thousands of robots,” said Waters. “If a robot runs out of charge, a person has to bring a charger.”

“We can offer autonomous charging, and with the interoperability standard, we can programmatically control for each battery, so that a Vector or MAV3K gets the right amount and show that they're charged,” he said. “Think of the energy efficiencies. We can optimize for the logistics of charging, depending on shifts, availability, and quiet periods. Robots can charge faster or slower, depending on the time of day.”

“If a station is occupied, it can publish that information, same as for an AMR,” Waters explained. “Over time, recognizing charging stations could be learned rather than programmed.”

Such status information could eventually come from other devices, including stationary ones, but MassRobotics narrowed its focus to basic location to start.

MassRobotics is also looking at recharging hydrogen cells, noted Theobald. “An unintended benefit of improving interoperability is creation of a new pieces of the industry,” he said. “This opens the door for someone to make a device that attaches to a forklift. When you have network-based data from devices, you can know the location and status of anything that's instrumented.”

Interoperability efforts converge

In addition to A3, MassRobotics, and ROG, the Advanced Robotics for Manufacturing (ARM) Institute is working on an interoperability project with Siemens, FedEx, Yaskawa, Waypoint, and the University of Memphis. Since some of the participants are in multiple groups, they are able to coordinate efforts and focus on different aspects of the challenge.

“Now that the MassRobotics standard is published, they can use it in their projects where it's applicable,” said Walker. “We've been talking with anyone who will listen about this, and customers should push for adoption. Because it's lightweight, there's no fear if they decide to follow it.”

At the A3 panel on “Interoperabilty for AMRs: Exploring the Path Forward,” Pestoni and Jose Luis Susa Rincon, project manager at Siemens, explained how Europe's VDA 5050 standard focuses on sending commands as well as data.

FedEx wants everyone to get involved

At least seven companies have adopted the MassRobotics standard so far, said Vecna's Theobald.

“The goal is for people using robots to be able to manage them themselves,” said Waypoint's Walker at an interoperability panel at FabTech last month. “We're striving for iPhone-level ease of use. The strength of the MassRobotics standard is that it is easy to adopt.”

Any company can self-certify to adopt the open-source standard, which is available through MassRobotics' Web site and on GitHub.

“FedEx wants everyone onboard,” said Aaron Prather, senior technical advisor at FedEx, which handles much of the world's shipping. “The efforts at MassRobotics and A3 will benefit both Fortune 500 and small companies. We want to help small and midsize manufacturers because they ship stuff.”

The tour of FedEx's 110,000-sq.-ft. R&D facility included a virtual tour of the company's operations, which handle 1.5 million packages nightly, as well as a demonstration of Boston Dynamics' Spot quadruped robot working with a drone for security.

Robotics 24/7 will soon post more coverage from A3's AMR & Logistics Conference.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up