Robotics suppliers have focused on ease of use as a differentiator and a necessary step toward wider adoption of automation. Mitsubishi Electric Automation Inc. this week launched a machine tending offering for its LoadMate Plus product line that it said is easy to implement.

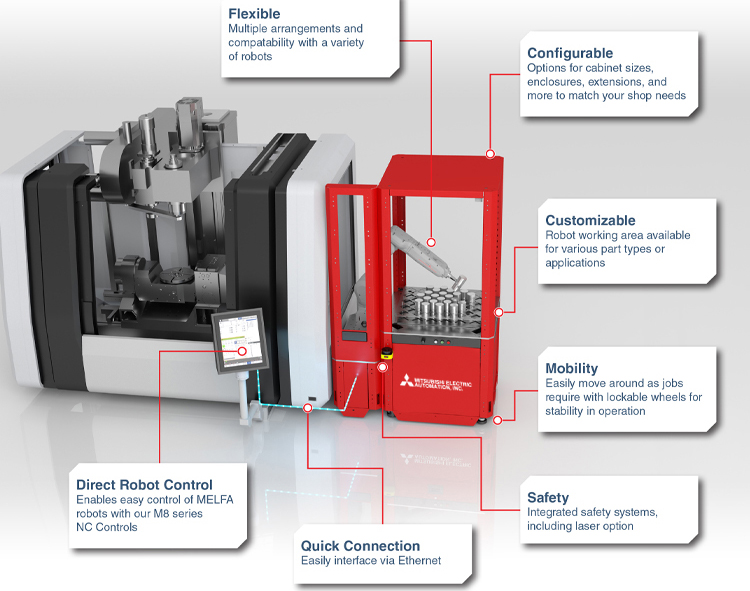

Mitsubishi Electric Automation claimed that its machine tending systems can improve productivity and reduce operating costs. The LoadMate Plus product line also offers flexibility and mobility to address skilled labor shortages in manufacturing, it said.

“Mitsubishi Electric Automation Inc.’s machine tending solutions portfolio provides a cost-effective answer to ongoing labor shortages and maximized productivity challenges many manufacturers are currently experiencing,” said Dave Simak, service product manager at Mitsubishi Electric, in a press release.

“Our experts work closely with your team to find and implement a turnkey solution that is seamlessly integrated, fully supported, and delivers ROI [return on investment] quickly,” he added.

LoadMate Plus for machine tending

Machine tending is the process of loading and unloading parts or materials into a machine tool center, most commonly used with vertical machining center mills and turning centers or lathes, including CNC Swiss machines.

Mitsubishi said its Electric M8 Series includes flexible connectivity via Ethernet and easy programming through its Direct Robot Control (DRC) feature. It enables machine tending to benefit customers that may not have experienced robot programmers available, said the company.

In addition to DRC, almost any CNC machine can be connected to a shop floor via discrete I/O for non-M8 CNC controls from Mitsubishi Electric and other companies. It said further support is available from Mitsubishi Electric trained engineers to service both the robots and CNC machines.

Mitsubishi Electric Automation also offers a five-year robot maintenance and warranty program.

About Mitsubishi Electric Automation

Vernon Hills, Ill.-based Mitsubishi Electric Automation is a U.S. affiliate company of Tokyo-based Mitsubishi Electric Corp. Its product portfolio includes programmable automation controllers (PAC), programmable logic controllers (PLC), human-machine interfaces (HMI), and variable frequency drives (VFD).

Mitsubishi Electric Automation also provides servo amplifiers and motors, control software, computerized numerical controllers (CNC), motion controllers, industrial and collaborative robots, and low-voltage power distribution products.

Article topics

Email Sign Up