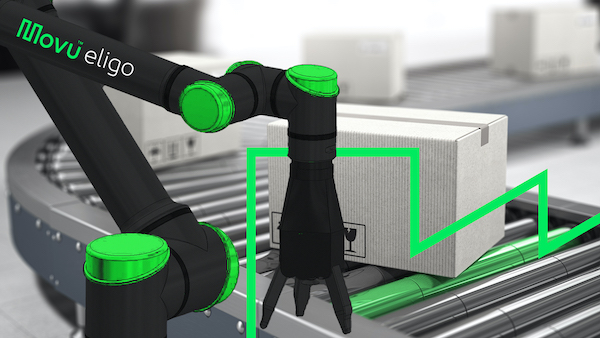

Movu Robotics, a leading supplier for designing, developing, and implementing innovative and easier warehouse automation solutions, unveiled a new robot picking arm designed to close the gap between manual and fully automatic pick operations.

The Movu eligo is a fully integrated robotic bin picking solution developed in close collaboration with Righthand Robotics. Movu eligo can automatically piece-pick from a single-SKU source bin and place the individual items into multiple mixed-SKU destination bins, providing warehouse operators with a huge step forward in order picking. The robot also helps solve labor shortage issues via its ability to work at inconvenient hours at reduced cost, but with higher pick accuracy and quality.

Other key benefits include:

- Reliable and effective robotic picking of up to 600 items per hour at any time;

- Enabling the picking and placing of a wide variety of SKUs;

- Providing a unique plug and play sub-system that is integrated with the Movu escala bin shuttle, resulting in an innovative end-to-end automated solution from storage to picking;

- Easy way to automatically pick SKUs that are suited for robotic picking, store the bins, and then finish the order with a manual pick when the time is convenient;

- Reduced cost per pick resulting in a strong Return on Investment (ROI).

Provided with seamless integration as a pick station option for the Movu escala bin shuttle, the Movu eligo combines advanced software with intelligent grippers and machine vision to ensure reliable throughput. The robot will gently grasp an item from a bin retrieved from the escala while picking and then placing the item in a delivery bin. Based on feedback, the intelligent grippers ensure accuracy and a gripping success rate of 100%. In addition to the low gripping failure rate, the Movu eligo reduces the number of manual ‘touches’ required for order fulfilment or replenishment and can reach a pick success rate greater than 99%, officials claim.

Able to achieve 600 picks per hour, depending on the specific implementation, the robot can pick goods up to 2 kg and with dimensions of 1 cm minimum to a maximum of 30 cm. The robot is also completely product agnostic, ensuring the flexibility to handle changing product mixes.

The robot arm stands 2.2 metres high and has an operating radius of 1.3 metres. A safety interface makes robotic work cells safe when human interaction is required.

Driven by software, the system leverages machine learning to continuously improve picking. Movu eligo runs on a plug-and-play Application Programming Interface (API) which integrates directly with the Movu escala bin storage solution. This user-friendly complete solution allows the seamless integration of robotic and manual picking operation for maximum efficiency. Movu escala interacts with overlying Warehouse Management Software (WMS), Warehouse Control Software (WCS) and Warehouse Execution Software (WES) as needed to mission the piece picking operations. By planning tasks for the robot such as robot arm movements around the source and destination bin exchange phases, the software optimizes pick cycle times to maximize throughput.

Real-time operational data is presented to staff stationed away from the active systems to resolve exceptions quickly and efficiently. Performance dashboards enable warehouse operations to visualize current and historical data.

Available with full 24/7 support, the Movu eligo allows customers, particularly those involved in pharmaceuticals, apparel, e-commerce, manufacturing and kitting, to realize the benefits of reliable robotic piece-picking without worrying about end-to-end integration.

“Movu eligo is a data-driven, intelligent piece picking platform … that automates conventional manual operations and results in a lower cost per pick,” said Stefan Pieters, CEO of Movu Robotics. “Integrated seamlessly as a work station for the Movu escala bin storage system, eligo offers a flexible and scalable automation solution for predictable and accurate order fulfilment, adding value for warehouses pursuing improvements in efficiency, productivity, and customer service levels.”

Watch this video for a look at how Movu eligo works.

Article topics

Email Sign Up