Glucose monitoring is critical for diabetics. In the past, they had to test their glucose via painful finger pricks or using embedded sensors under their skin. There are now biosensors that measure glucose levels in sweat, which are less painful and invasive, but these flexible sensors are typically created via screen printing, a process that is wasteful and relies on the use of toxic materials.

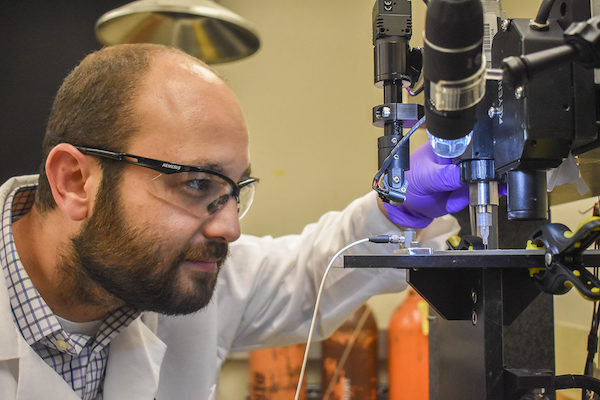

Researchers at Washington State University have found a way to produce flexible glucose sensors using 3D printing via direct ink writing. They are using a nanoscale material that is electrically conductive and flexible, and claim to be able to produce biosensors that are more accurate using production methods that are less material intensive.

The team, led by Arda Gozen and Yuehe Lin of the School of Mechanical and Materials Engineering, published their research in Analytica Chimica Acta.

The wearable sensors could make it easier and less painful for diabetics (especially children) to monitor their glucose, while also reducing costs. According to the researchers, the glucose monitors created through 3D printing are more stable and sensitive than those manufactured through traditional methods.

The WSU technique allows a precise application of the nanoscale material, “resulting in a uniform surface and fewer defects, which increases the sensor’s sensitivity.”

The 3D‑printed sensors were better at picking up glucose signals than the traditionally produced electrodes. The sensors can also be customized for each person’s biology.

“3D printing can enable manufacturing of biosensors tailored specifically to individual patients” Gozen said.

For more widespread adoption, the printed biosensors would need to be integrated with electronic components on a wearable platform — the researchers are currently planning to integrate the sensors in a packaged, wearable system that can be used for long-term glucose monitoring. 3D printers could also produce the electronics and other components of a wearable glucose monitor, which the researchers say could help reduce and consolidate manufacturing costs.

“Our 3D printed glucose sensor will be used as wearable sensor for replacing painful finger pricking. Since this is a noninvasive, needleless technique for glucose monitoring, it will be easier for children’s glucose monitoring,” Lin said.

Source: Washington State University

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up