Additive manufacturing (AM) has staked its claim in manufacturing by asking users, “What do you want to build?” and offering the means to make digital dreams into physical reality. The next question AM will need to answer is, “What material best suits your vision?” The answer to the second question may well decide the long term growth of 3D printing.

A new report from Market Research Reports seems to suggest the materials industry has taken the question seriously, and is working to ensure tomorrow’s 3D printers have a wealth of material options. According to the report, sales for AM materials will surpass 3D printer sales by 2023, reaching $8.3 billion in sales by 2025.

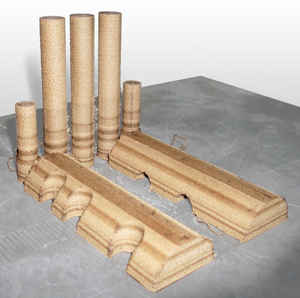

Wood is one material that has only recently become available for use in 3D printing. Courtesy of Kaipa.

Wood is one material that has only recently become available for use in 3D printing. Courtesy of Kaipa.Market Research Reports cites a number of factors that account for the boom in AM materials research, the first of which is patent expiration. When key AM patents were held by a small number of companies, growth in the industry proceeded at a slow and steady pace. As more patents expired, it opened the way for smaller (and perhaps more agile) companies, prices began to drop and consumer interest rose.

Even discounting interest in plastic filament driven in part by sales of home 3D printers, the use of AM has grown in a number of industries, including medical, aerospace and automotive. The interest shown in AM by large and cash rich industries is the second factor that has led to increased efforts at AM material development.

Not every material has the same potential for future growth. Some, such as metal powders, are already in high demand. The materials investigated in the report include:

- Photopolymers

- Thermoplastic filaments

- Thermoplastic powders

- Metal powders

- Sand and binder

- Welding wire

- Plaster

Below you’ll find a video from Oak Ridge National Laboratory about the future of AM.

Source: Market Research Reports

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up