Last year I underwent surgery to have a ganglion removed from my shoulder. Naturally curious about what the doctors would be doing to me, I looked up details about the procedure and found two different methods. The old method involved slicing open my shoulder to the bone, removing the ganglion, after which I could look forward to months of rehab. The more modern solution was a tiny trio of holes through which equally tiny surgical equipment would be inserted to remove the problem. Option two resulted in two months of rehab.

Option two has pretty much become the preferred method for most surgeries. The smaller the incision, the less recovery time required, and the smaller the scars left by surgery. Medical engineers have been working on reducing the size of surgical tools, but have nearly come to the limit of what is possible. Rather than give up, researchers at Brigham Young University (BYU) have begun to experiment with new principles of design based on origami and prototyped with additive manufacturing (AM).

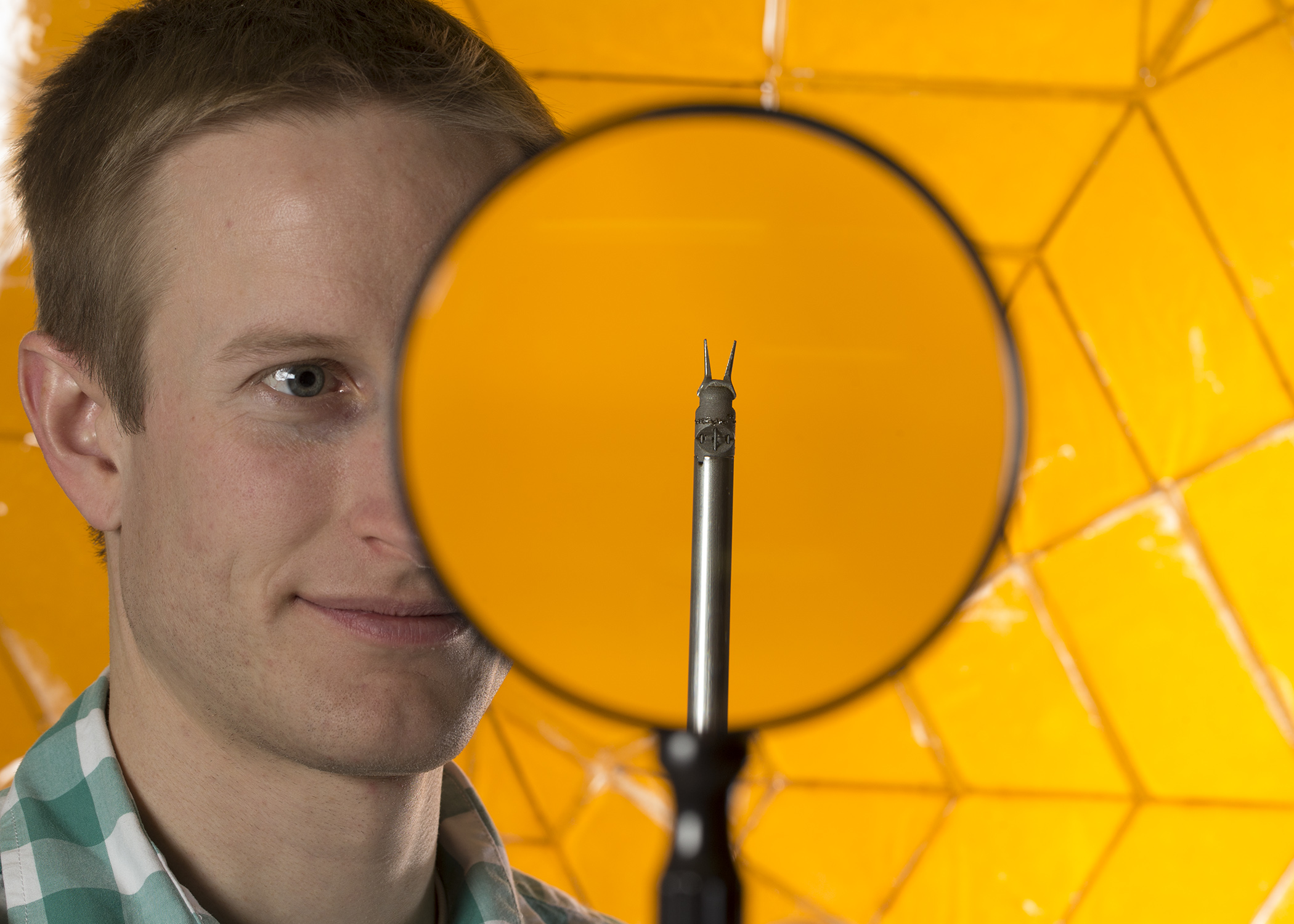

New surgical tools developed at BYU use principles of origami for miniaturization. Courtesy of BYU.

New surgical tools developed at BYU use principles of origami for miniaturization. Courtesy of BYU.“Those who design spacecraft want their products to be small and compact because space is at a premium on a spacecraft, but once you get in space, they want those same products to be large, such as solar arrays or antennas,” said Spencer Magleby, mechanical engineering professor at BYU. “There’s a similar idea here: We’d like something to get quite small to go through the incision, but once it’s inside, we’d like it to get much larger.”

While the research team might have drawn inspiration from origami, the idea of small probe transforming into larger instruments during use is an old staple of science fiction. AM will help make science fiction into science fact by accelerating the iteration cycle making it easier for the team to fail early without spending large sums of money on functional prototypes built by hand.

The eventual goal of the miniaturization of surgical tools is to allow surgeons to make such small incisions that no sutures are necessary for post-op healing. Imagine if major surgery could be performed without slicing through muscle or the incision could be kept clean and covered with a simple bandage.

Below you’ll find a video about the research.

Source: BYU

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up