Editors’ Picks

Found in Robotics News & Content, with a score of 3.24

…material handling, pick-and-place, palletizing, machine tending, injection molding, and inspection applications. It is compatible with the company’s YRC1000 and YRC1000micro controllers. Yaskawa Motoman's Pallet Builder interface is a free, easy-to-use software for the company's Smart Pendant. Source: Yaskawa Motoman In addition to programs created by technology partners, Yaskawa offers its own installation packages for the Smart Pendant, including Pallet Builder. Andrzejewski said Pallet Builder is a free, easy-to-use application for configuring palletizing cells. It’s suitable for single case palletizing with support for up to eight total stations. Through Pallet Builder, users teach robots how to arrange boxes on a pallet,…

Found in Robotics Companies & Businesses, with a score of 14.01

Advanced robotics. Advanced cleaning. When only the highest cleaning quality standards are acceptable, our robots' proven reliability and durability ensure your facility stays clean. Rugged construction, extended runtime, separate cleaning solution and recovery tanks - you can rely on Avidbots’ solutions to deliver a cleaner, more productive facility.

Found in Robotics News & Content, with a score of 5.85

…Industrial Robots (MiR). Last week, UR demonstrated an autonomous inspection system powered by NVIDIA Isaac cuMotion path planning at the GTC global AI conference in San Jose, California. MiR recently launched its new MiR1200 autonomous pallet jack, which harnesses AI pallet detection powered by the NVIDIA Jetson AGX Orin module. The MiR1200 Pallet Jack and UR’s cuMotion demo are Teradyne’s two most recent examples of “physical AI” systems, with others already available through Teradyne Robotics’ ecosystem partners, OEMs, and end users, the company said. Ujjwal Kumar, group president of Teradyne Robotics, said the recent examples are the first of a…

Found in Robotics News & Content, with a score of 7.97

…community.” The three selected projects were: Robotic non-contact 3D inspection replacing hard gaging Organization: ARIS Technology ARIS Technology will replace manual hard gauging with robotically automated non-contact 3D scanning, qualifying parts with data instead of manual testing. The team will demonstrate a fully integrated robotic 3D scanning system at the Iowa Army Plant. Extended Reality and AI-Assisted Paint Masking Organization: GridRaster Inc. GridRaster will refine and deploy their extended reality tools to enable optimized paint masking work on a large Army vehicle in the operational environment at Letterkenny Army Depot. This effort is anticipated to lower masking errors and reduce…

Found in Robotics News & Content, with a score of 24.67

…helped attendees discover how machine vision can automate manufacturing inspections. Attendees saw advanced 2D, 3D and deep learning options to automate their manufacturing processes and solve inspection challenges that traditional machine vision cannot. For example, demonstrations showed: Flowchart-based software for quickly building machine vision applications 4Sight series of fanless or expandable vision controllers High-fidelity 3D laser profile sensors boasting a dual-camera single-laser design Complete set of industrial quality deep learning tools Deep learning OCR tool that requires no training Peak demonstrations at MODEX At the show, Peak ran two machine vision demonstrations. First, it demonstrated how users can develop and…

Found in Robotics News & Content, with a score of 8.43

…the attendees can use Olis to run a tool inspection routine and perform remote error recovery, allowing the robot to resume its cycle and get back to work. “We’re incredibly excited to start working with Kawasaki integrators to deploy and retro-fit Olis units with Kawasaki robot arms,” said Fredrik Ryden, CEO at Olis Robotics. “Kawasaki’s commitment to a world-class buying experience and quick ROI in a wide range of applications is a perfect match for Olis.” Ryden also highlighted Kawasaki’s robotic durability, giving end users maximum control of a highly customizable product. Another key element of the partnership he noted…

Found in Robotics News & Content, with a score of 13.40

…showing the user live robot locations, active missions and inspection alerts. Users can create and modify mission recordings, allowing organizations to record multiple sessions – with multiple robots over multiple days – and merge this information into a single map in Orbit. The offering also creates more mission scheduling flexibility to loop based on user-designated preferences. For example, users can choose to loop within a launch window, specific days and times or other designated timeframes. Timeframes can also include exclusions, such as weekends or other downtimes. Orbit is currently available as a cloud offering for North American customers, with more…

Found in Robotics News & Content, with a score of 7.89

…mains in the U.S. and U.K. over the previous 15 years. It’s robotics-as-a-service (RaaS) offering helped enable gas pipeline inspection and repair with minimal disruption to the public.

Found in Robotics News & Content, with a score of 7.59

…smart factory will run lights-out production, and that integrated inspection will be the critical ‘eyes & ears’ of autonomous manufacturing.” Zaptic was selected for its connected worker platform for manufacturing that digitizes operations. “It’s an honor to be selected as a winner for Sixth Sense,” said Sandy Reid, co-founder and CCO at Zaptic. “Manufacturers desperately need a more efficient way to secure and build capability in the workforce. Partnering with Hexagon will allow us to meet this need at scale with Zaptic’s AI-guided connected worker solution.” The cohort winners will be given access to Hexagon's resources for global expansion, including…

Found in Robotics News & Content, with a score of 13.73

…that allow for navigating even narrower passageways, smart tray inspection based on visual sensors and more color options. In 2024, restaurant and retail customers expect seamless experiences tailored to their preferences by brands that can anticipate their next desire. Businesses facing an unprecedented labor shortage are turning to robots to deliver such an experience. In addition to delivering food and returning items, KettyBot can attract, greet and guide customers in dynamic environments while generating advertising revenue, reducing overhead and enhancing the in-store experience. KettyBot in the restaurant robotics industry “We hear from various businesses that it’s hard to maintain adequate…

Found in Robotics News & Content, with a score of 9.68

…riveting, and dispensing to flow drilling and ultrasonic weld inspection. Each package is a ready-to-use, customer-proven combination of hardware, software, and services and will be implemented at Volvo Cars’ facilities in Torslanda, Sweden, and Daqing, China. Alongside the hardware and functional packages, ABB’s latest range of OmniCore robot controllers will help deliver energy savings of up to 20 percent at sites due to their highly efficient power electronics and use of regenerative braking within the robot. “The automotive industry’s historic transformation, driven by increasing consumer demand for electric vehicles and a desire to operate more sustainably, is creating new opportunities…

Found in Robotics News & Content, with a score of 11.81

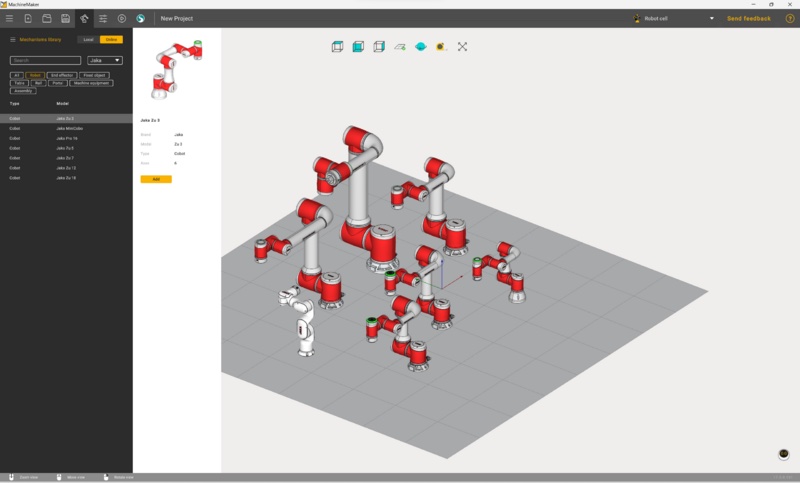

…They are versatile, used in assembly, welding, machine tending, inspection, testing, dispensing (painting, coating, gluing, bonding), and finishing applications (polishing, grinding). To program JAKA cobots with SprutCAM X Robot, users should download and install the requisite software. https://sprutcam.com/download/ A free 30-day fully functional license will be granted automatically. The next step involves opening MachineMaker, an application for creating digital twins of industrial robots in SprutCAM X Robot, and finding the appropriate cobot in the online Robot Library. The developers of SprutCAM X Robot have plans to support the full range of JAKA Robotics models. They are also committed to expanding…