Editors’ Picks

Found in Robotics News & Content, with a score of 17.24

…the following components: Six-axis robotic arm Custom end-of-arm tool (EOAT) AI powered machine vision Integration with the WES AI enables a comprehensive, intelligent system Unlike traditional industrial robotic applications, these bin-picking robots aren’t trained to do a singular task with set inputs and outputs. Thanks to artificial intelligence, the robots can problem solve for an infinite amount of new and complex situations, like new SKU integration, with no training required. When an inventory bin is presented to the machine vision system, a photo is taken to map out the objects’ orientations. Within a split second, AI vision identifies the “most…

Found in Robotics News & Content, with a score of 17.17

…Tool changing increases in speed, importance As end-of-arm tooling [EOAT] technologies improve in precision and more industries look to automation, gripper makers have kept busy. Software advances are big driver, as user interfaces have become easier to use. On the hardware side, there are new engineering feats such as the introduction of seven-axis collaborative robots and new grippers outfitted with force sensors. Customers are always asking for more precision, speed, and flexibility, Green said. Getting customers the systems they desire takes a combination of many different types of technologies. “You really need to marry a number of different technologies into…

Found in Robotics News & Content, with a score of 15.80

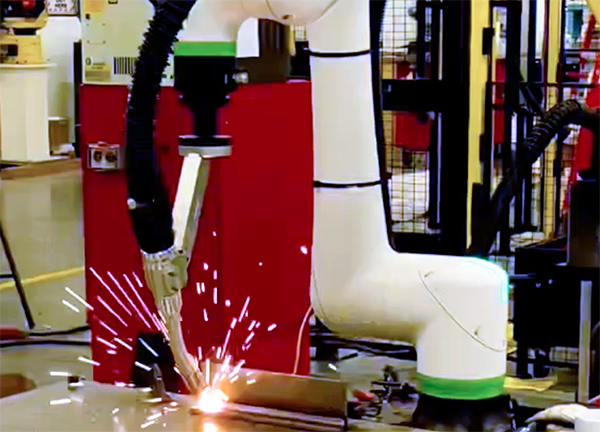

…FastARC CX1000 can be available for delivery and installation within just weeks, according to Acieta. With many end-of-arm tooling (EOAT) options, the CX1000 can be uncoupled from the weld cart and repurposed for different applications such as machine tending or sanding when not welding. The FastARC CX1000 cobot is equipped with a FANUC six-axis, 10-kg (22 lb.)-capacity cobot arm that Acieta said is maintenance-free for up to eight years. The system is compatible with Lincoln Electric and Miller Electric welders and is IP 67-rated with sealed components to work in industrial environments.

Found in Robotics News & Content, with a score of 15.69

…a 12 kg payload capacity, hollow wrist for reliable EOAT cable management and a 1,440-mm horizontal reach. The OTTO 1500 offers a payload capacity of 3,300 lbs. and is built with industrial grade components. It is designed to increase throughput, reduce operating costs and remain flexible with the changing needs of material flow processes. “We’re really excited to partner with Yaskawa to develop the future of mobile manipulation and collaborative robots,” said Matt Rendall, chief executive officer at Clearpath. “Combining our cutting-edge self-driving industrial vehicles with Yaskawa’s industry-leading robot arms will enable a new category of automation for machine tending.”…

Found in Robotics News & Content, with a score of 15.58

…vacuum gripping system, interfaces towards common (industrial-standard) end-of-arm tooling (EOAT), and stand-alone mounting, said Piab. The patented COAX vacuum technology is designed for flexibility and ease of maintenance, making it suitable for challenging robotics applications and devices where safety is a key concern, claimed the company. In addition, Piab said piSAFE offers the following benefits: Vacuum safety non-return valve (check valve), which holds vacuum in sealed applications in case of a system or power failure Configurations for both centralized and decentralized vacuum systems Can replace more expensive mechanical or vacuum-tank safety arrangements in robotic tools and ergonomic equipment Suitable in…

Found in Robotics News & Content, with a score of 15.26

…lb.). Thanks to a telescopic linear air-operated actuator, the EOAT can grasp parts the size of a golf ball or small blister pack, depending on the suction cup arrangement. It can hold a wide range of shapes and surfaces, even loose or nonrigid objects, said the company. The MAXXgrip's actuation is designed so it can be executed in parallel with the approach/depart motion segments used in pick-and place cycles. Its response time is 0.15 to 0.4 sec., but as this motion typically takes around the same time for the robot arm to move, it minimizes dwell time in successive picking…

Found in Robotics News & Content, with a score of 14.97

…of the mobile robot world Just as end-of-arm tooling (EOAT) make it possible for industrial robots such as collaborative robot arms to actually grasp and manipulate objects, mobile robotic equipment makes it possible for an AMR to successfully collect goods and transport them through a facility. And just as cobots are components within an overall automation deployment that requires EOAT, AMRs are components of a complete mobile automation deployment that requires MREs. Without doubt, not all equipment is created equal, and there are significant differences in terms of functionality, usability, and compatibility among various offerings, but without MRE of some…

Found in Robotics News & Content, with a score of 14.14

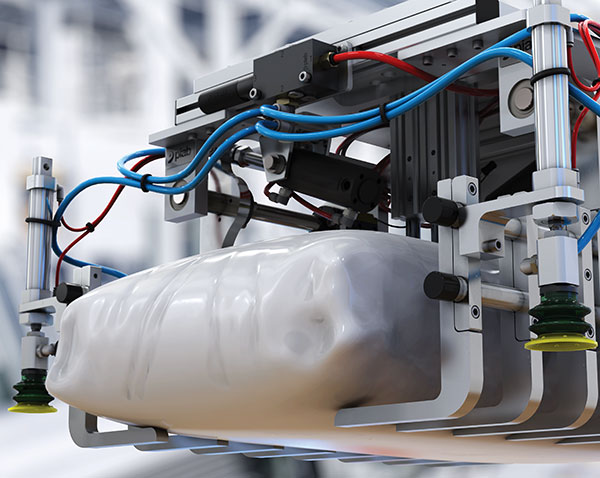

…our long experience from developing custom palletizing end-of-arm tooling (EOAT),” stated Madeleine Sheikh, product manager at the Piab Vacuum Automation Division, in a release. “What we have here is a complete pre-engineered bag gripper that is easy to install, adjust and maintain,” she added. “It offers flexibility to fit any roller conveyor on the market, and slip sheets are handled just as easy by our vacuum-based upgrade option with Duraflex suction cups and COAX technology.” Piab Group has sold gripping, lifting, and moving systems since 1951. The Täby, Sweden-based company said automation can eliminate resource waste and worker injuries. It…

Found in Robotics News & Content, with a score of 14.12

…the intelligence to choose and select different end-of-arm tools (EOAT), and then ascertain the precise grasp pose to avoid interfering with adjacent cases. “Depal is a warehouse workflow characterized by heavy use of manual labor and high levels of workplace injuries,” said Motohiro Kawada, CEO of IHI. “Addressing this challenge aligns closely with our corporate mission of designing and building progressive engineering solutions for people and the planet… Our decision to move forward with OSARO is based on their ability to handle a wider variety of boxes at much faster recognition speeds than other vendors.” OSARO’s Sightworks machine-learning software maximizes…

Found in Robotics News & Content, with a score of 13.78

…availability, and productivity.” Robot arms placed with end-of-arm tools (EOAT) are also on display taking advantage of SICK’s object detection technologies. “On display at PACK EXPO, you’ll see how robot arms are enhancing picking and how they can create a safe and productive work environment,” the company said. More on PACK EXPO SICK is located at booth N5929 on the trade show floor. It will also be hosting several demonstrations and one educational session focused on intelligent sensors, robotic end-effectors, and vision solutions. PACK EXPO in Chicago is put on by the Association for Packaging and Processing Technologies and features…

Found in Robotics News & Content, with a score of 13.75

…but also eliminates the need for specialized end-of-arm tooling (EOAT) and force sensing during sanding tasks.” An EsVata staff member operates Flexiv’s Rizon 4 adaptive robot arm with an OnRobot sander attached to the universal mounting flange. Source: Flexiv Robotics By automating sanding, EsVata’s employees are now freed from monotonous, labor-intensive sanding tasks, which enables them to engage in more valuable roles within the company. Flexiv said this reallocation of human resources underscores EsVata’s commitment to enhancing employee satisfaction, and highlights its belief in enhancing the impact of human labor through collaborative robotics rather than replacing it. Customized interface, universal…

Found in Robotics News & Content, with a score of 13.16

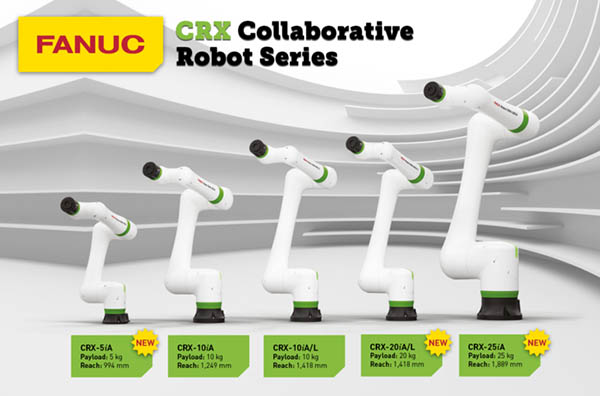

…models are designed to be easy to connect to third-party devices, including FANUC-approved CRX device suppliers for end-of-arm tooling (EOAT), grippers, accessories, and plugins. Industrial automation suppliers interested in having their products become part of the CRX device program should contact FANUC. Demos and shipping to come FANUC plans to demonstrate all five CRX models at IREX (International Robot Exhibition) Virtual from March 1 to 18, and at IREX from March 9 to 12, at the Tokyo Big Sight in booth E4-04. The company said it will begin shipping production units of the new CRX-20iA/L in April. The CRX-25iA and…