Robots offer the possibility of more efficient and profitable recycling, keeping more waste out of landfills. The Can Manufacturers Institute today said it is using an innovative financing model to deploy a robot at a Caglia Environmental material recovery facility, or MRF, in California.

Ardagh Metal Packaging and Crown Holdings, two members of the Can Manufacturers Institute (CMI), will fund a two-year equipment lease for a robot from EverestLabs. The companies said they expect the robot to capture more than 1 million used beverage cans (UBCs) a year at the Caglia MRF, which sorts single-stream recyclables.

Caglia will share with CMI 50% of all revenue from the UBCs captured with the leased equipment, including the revenue from the sale of the UBCs and the revenue from California’s deposit-return system. The lease program is the latest in a several-year CMI effort to demonstrate the potential additional revenue from capturing missorted UBCs and to encourage the adoption of additional equipment in MRFs.

More value to be captured, says CMI

The potential to capture missorted UBCs at material recovery facilities is significant, said the Can Manufacturers Institute. Its 2020 research, “Aluminum Beverage Can: Driver of the U.S. Recycling System,” found that up to one in four aluminum beverage cans is missorted at a typical MRF.

CMI also supported testing at five loss points across three diverse MRFs in 2022. It found an average loss of seven to 36 UBCs per minute, which represents an annual average revenue loss of $71,900.

The payback period was three years, according to the return-on-investment (ROI) calculator that CMI commissioned and published online for MRFs to use.

The Can Manufacturers Institute is the national trade association of the metal can manufacturing industry and its suppliers in the U.S. The industry accounts for the annual domestic production of approximately 130.7 billion food, beverage, and general line cans.

It also employs more than 28,000 people with plants in 33 states, Puerto Rico, and American Samoa and generates about $15.7 billion in direct economic activity. CMI said its members are “committed to providing safe, nutritious, and refreshing canned food and beverages to consumers in the most sustainable packaging.”

CARTS continually upgrades waste handling

The Caglia family has provided solid waste and recycling services to the San Joaquin Valley and the Fresno area for over 80 years. Orange Avenue Disposal began in 1941 and has expanded over the years to Cedar Avenue Recycling Transfer Station (CARTS), Industrial Waste & Salvage (IWS), and Red Rock Environmental Group in Madera County.

Started in 2004, the CARTS facility in Fresno, Calif., represents the latest generation of MRF, said Caglia. Unlike a traditional garbage dump, it is a fully integrated materials recovery campus, processing trash, construction/demolition debris, green waste/organics, concrete, and asphalt.

It also processes single-stream recycling from commercial, government, industrial, and residential customers from all over the Central Valley. As one of the largest and most advanced MRFs in Central California, CARTS has been recognized for its local sustainability efforts and state-of-the-art technology.

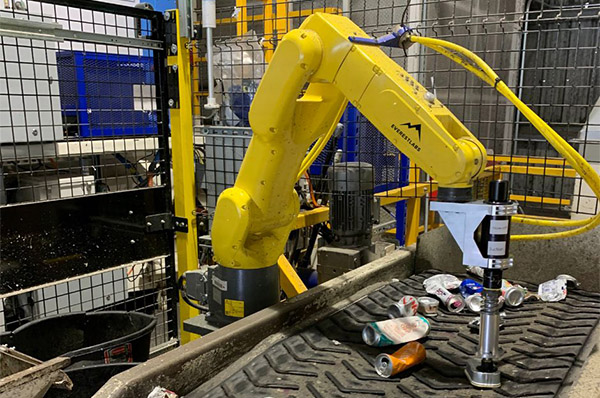

Even at a MRF such as CARTS, there is the potential to capture additional cans. This facility, which focuses on continuous improvement, will place the leased robot on its “last chance line” to capture UBCs mistakenly sorted to material destined for landfill.

“We put EverestLabs’ robot on the last-chance line and have it focusing on aluminum beverage cans so that it’s picking ‘gold’ out of the trash,” said Corey Stone, plant maintenance manager at CARTS. “This lease provides a no-risk, no-cost way for Caglia to advance its goal of capturing all recoverable material coming through its facility.”

“EverestLabs’ real-time and easy-to-use analytics platform, alongside an easily retrofittable robotic cell with zero disruptions and guaranteed highest recovery in the industry, ensures all possible UBCs are recovered,” Stone said. “With CMI wanting to recycle more aluminum beverage cans and Caglia becoming a recycling industry leader, this program is a win-win for everyone.”

EverestLabs RecycleOS to improve recovery rates

EverestLabs has developed RecycleOS, which it claimed is only enterprise artificial intelligence, analytics, and automation system for recycling plants. MRFs can use it to increase materials recovery, and manufacturers can then reuse recyclables, thus preventing greenhouse gas emissions and energy usage for making virgin packaging, it said.

The Fremont, Calif.-based company is funded by leading American, Canadian, and Japanese venture funds.

“EverestLabs is delighted to partner with Can Manufacturers Institute, Crown, Ardagh Metal Packaging, and Caglia Environmental to increase UBC recovery using RecycleOS, our purpose-built AI and automation platform for MRFs and manufacturers,” stated Jagadeesh Ambati, founder and CEO of EverestLabs. “With new investment models, we can speed adoption of AI solutions to eliminate losing UBCs to landfill, as this is a massive loss for the entire ecosystem.”

Now that EverestLabs’ 3D depth-sensing camera, AI, and robot have been installed at Caglia’s Fresno MRF, the RecycleOS data platform is delivering daily reports on the number of missorted UBCs each day. It is also providing the economic value of these cans and the greenhouse gas emissions saved from recycling them.

Caglia expects results to scale

Caglia estimated with previously conducted vision studies and analysis that EverestLabs’ robot will capture 32,000 lb. of used beverage cans per year that otherwise would have gone to landfill. This is equivalent to collecting a little more than 1 million UBCs per year or around three UBCs per minute of operation.

So far, the equipment is seeing up to 1,400 UBCs per day and recovering a majority of them so they go into the circular supply chain rather than to the landfill, said the companies.

Caglia, the Can Manufacturers Institute, and EverestLabs said they plan to provide updates with further data after the equipment has operated for a longer period of time. Caglia plans to use the experience with this robot to see how else it can deploy technology at its MRF to maximize its recovery efforts.

CMI added that it intends to support additional recovery equipment and will use lessons from this first lease to refine its financing approach.

Ardagh and Crown look to sustainable costs

“We are excited about the lease model because it highlights that aluminum beverage cans are consistently one of the most valuable recyclable commodities and further exemplifies how this recycled beverage container pays its own cost of recycling due to that high market value,” said John Rost, vice president of global sustainability and regulatory affairs at Crown. “CMI research has concluded that without the vital revenue from UBCs, most MRFs would not be able to operate without a change to their business model.”

Along with this first lease, the Can Manufacturers Institute has also funded grants from The Recycling Partnership with capital from Ardagh Metal Packaging and Crown. The five grants funded in 2021 doubled expected performance, with 140 million aluminum beverage cans captured each year by the equipment installed with the grants.

Earlier this year, CMI announced that Ardagh Metal Packaging and Crown provided funding for additional grants that will be awarded through The Recycling Partnership.

“Considering metal recycles forever—with 93% of recycled aluminum beverage cans turned into new cans and recycled aluminum 94% less carbon-intensive than making primary aluminum—it is imperative that recycling sortation facilities capture all cans for the aluminum industry to buy and recycle,” said Jens Irion, CEO of Ardagh Metal Packaging – North America.

“We are proud to have instituted a circular financing model for the textbook example of the circular economy – the aluminum beverage can,” Irion said. “The revenue from the cans captured with the leased equipment can be used to finance even more can capture equipment at additional MRFs.”

EverestLabs, CMI and Caglia Environmental will hold an Institute of Scrap Metal Industries (ISRI) webinar on “Industry Partnerships Driving AI and Robotics Deployment in MRFs” at 1:00 p.m. on Oct. 4.

Also, Scott Breen, CMI’s vice president of sustainability, will discuss the lease program during a panel at the Paper and Plastics Recycling Conference in Chicago on Oct. 12.

Article topics

Email Sign Up