Epson Robots today released updates to its VT6L robot arm and Epson RC+ Express management software.

The Los Alamitos, Calif-based company is now selling a direct current (DC) powered version of the VT6L 6-axis robot. It said it developed the model for mobile manipulation purposes since the robot arm can be placed on top of an autonomous mobile robot that is also DC-powered.

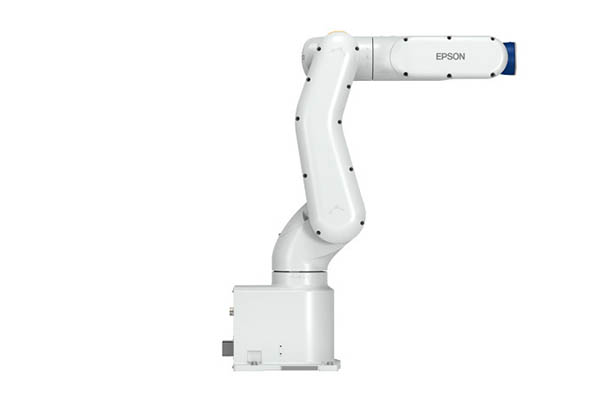

Epson’s DC-version six-axis robot arm can be installed on AMRs

Everything else about the robot is the same as the alternating current (AC) version. It has a reach of 900 mm (35 in.) and payload capacity of 6 kg (13 lb.). It also has a built-in controller.

“No longer does it have to be tethered to the wall essentially,” Danielle Collins, a product manager at Epson Robots, told Robotics 24/7 in an interview. The company is estimating the new robot arm will be popular for material transfer and machine tending applications.

Customers in those industries want the flexibility of having a robot arm that can more freely navigate a facility and be used in many parts of a supply chain operation at any given time. That can be useful in situations where a facility has multiple machines spread throughout a facility that run at different times and require items to be loaded and unloaded, she noted.

“Now you can put a robot on a mobile workstation and move it between operating centers,” she said.

Updates to Epson RC+ Express

Customers control the robot using two robot development programs—Epson RC+ and Epson RC+ Express. Epson RC+ is the company’s more advanced control navigation system that requires customers to code to interface with the robot. Epson RC+ Express, on the other hand, is a code-free more lightweight user interface that uses “a block-style robotic teaching environment.”

The company launched Epson RC+ Express last year, but today has introduced a host of new features to the development environment, including compatibility with more of Epson’s robots, along with expanded use case features and more integration options.

“As more businesses implement automation to address workforce challenges, Epson recognizes that more users require not only easy-of-use applications but also the flexibility to be mobile,” said Scott Marsic, group product manager at Epson Robots in a statement. “Epson is committed to providing a simplified automation experience. Solutions like the VT6L-DC empower warehousing, logistics and machine tending operators to move a traditional 6-Axis robot from place to place rather than mounting it in a single, stationary location. And, with simple, visual-based programming software like RC+ Express, users can get their robotic automation solutions up and running quickly.”

The company plans to showcase the new robot and operating system later this month at Pack Expo in Chicago and The Assembly Show in Rosemont, Ill.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up