Festo Didactic and SICK Sensor Intelligence today announced the creation of their Safety Awareness Bundle. Designed for students, the bundle includes lessons on robot risk assessment and the differences between the system approach and automation à la carte.

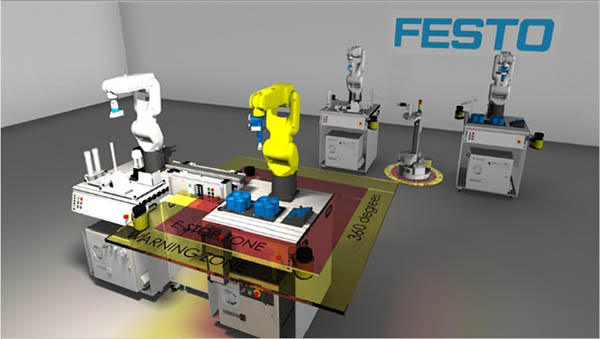

The bundle includes Festo Didactic’s manufacturing production system and a simulated cyber-physical smart factory with a six-axis robot. SICK’s area scanners, safety programming logic controllers, and safety relay are also included.

Industry should drive education

“With such a demand for Smart Manufacturing methods to be demystified, students who have been exposed to this sort of implementation have a real advantage when it comes to applying to jobs compared to students not provided the same experiential learning and job training,” said Ted Rozier, director of engineering at Festo Didactic North America.

The bundle includes a six-step safety guide for robotic equipment safety.

1. Risk assessment

2. Safe design

3. Technical protective measures

4. Administrative measures/information about residual risks

5. Overall validation of the machine

6. Deployment of machinery

Students will also learn the definition of the terms performance measure, areas of severity, frequency, and avoidance as they relate to robotics.

“In the past, robotics education has traditionally focused on a specific robot brand and only the robot operation itself,” Festo Didactic said in a statement. “By adding safety curriculum to FESTO’s product line MPS (Manufacturing Production System) and Cyber-Physical training equipment, students develop a well-rounded working knowledge of how robots are tightly integrated as a system in the real world.”

Curriculum designed for use in schools and by those already working in industry

FESTO and SICK said they designed the curriculum to be platform agnostic so any leading robotics manufacturer can adopt it. The bundle is being used at several community colleges and universities across the country, according to the companies. They added they are also offering the bundle to those working in the industry already as well.

“Incumbent workers may also sign up for the safety awareness course to upskill their robotic knowledge base,” the companies said. “After learning and performing the competency-based exercises in the curriculum, students acquire the in-demand skills they need to be successful at work and throughout their career.”

Susan Nangle, national key account manager at SICK, said the partnership lines up with the goals of SICK’s founder, Dr. Erwin Sick.

“SICK wants to make the world a safer place. It’s about educating students that safety is important. It’s about getting beyond the manufacturing site and taking a step back to those students before they even hit the plant floor, so they recognize the importance of machine safety,” Nangle said.

The companies also teamed up at IMTS 2022 and hosted a student competition.

Article topics

Email Sign Up