Meltio, which described itself as a leader in wire-laser metal deposition additive manufacturing, today announced the Meltio Space software. The company said Meltio Space is a toolpath generator designed to accelerate adoption of its technology and help users benefit from robotic 3D printing without requiring expertise in robotics or programming.

“Meltio Space makes it possible to design very reliable parts as quickly as possible and with a wider range of possibilities for our industrial customers,” stated Alejandro Nieto, Meltio Engine product manager. “This is thanks to a very user-friendly interface of the Meltio Engine Robot Integration.”

“The learning curve of our Engine integrators was very low because they depended on third-party software, and those developers do not have the knowledge that we can have in Meltio of the Meltio Engine,” he added. “So the main goal of our technology is to give the most efficient tool that allows the industry the most of the applications they need to manufacture metal parts with our wire-laser technology.”

Linares, Spain-based Directed Metal 3D SL, which does business as Meltio, has developed 3D printing systems using wire-laser metal deposition (LMD) technology, a directed energy deposition (DED) process. The multinational company said it provides high-performance, affordable, and easy-to-use systems for industrial customers, research-and-development organizations, and universities.

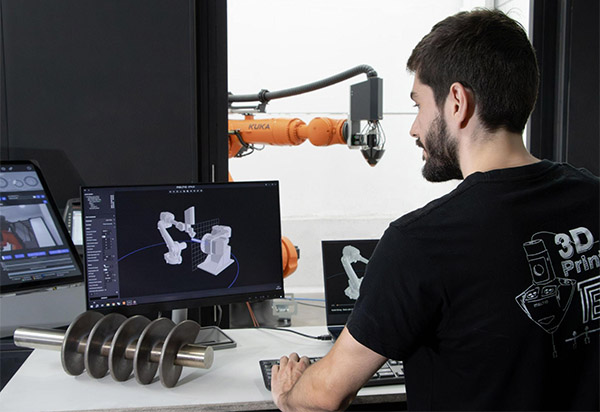

Meltio Space incorporates robotic manipulation into 3D printing

Meltio's product portfolio includes the Meltio M450 metal 3D printer and Meltio Engine Integration, a 3D printing module that it said “turns almost any CNC, robotic arm, or gantry system into a powerful hybrid manufacturing center.” Both systems use the company's patented LMD-based process to make parts of both wire and powder simultaneously with the same printhead.

Meltio Space is designed to “bridge the gap between additive manufacturing users and robotics,” according to the company. The new software integrates a six-axis robot manipulator and two-axis workpiece positioners to transcend traditional three-axis systems and open new possibilities for metal 3D printing, said Meltio.

The company claimed that it will increase the reliability and accuracy of additive manufacturing for metal parts.

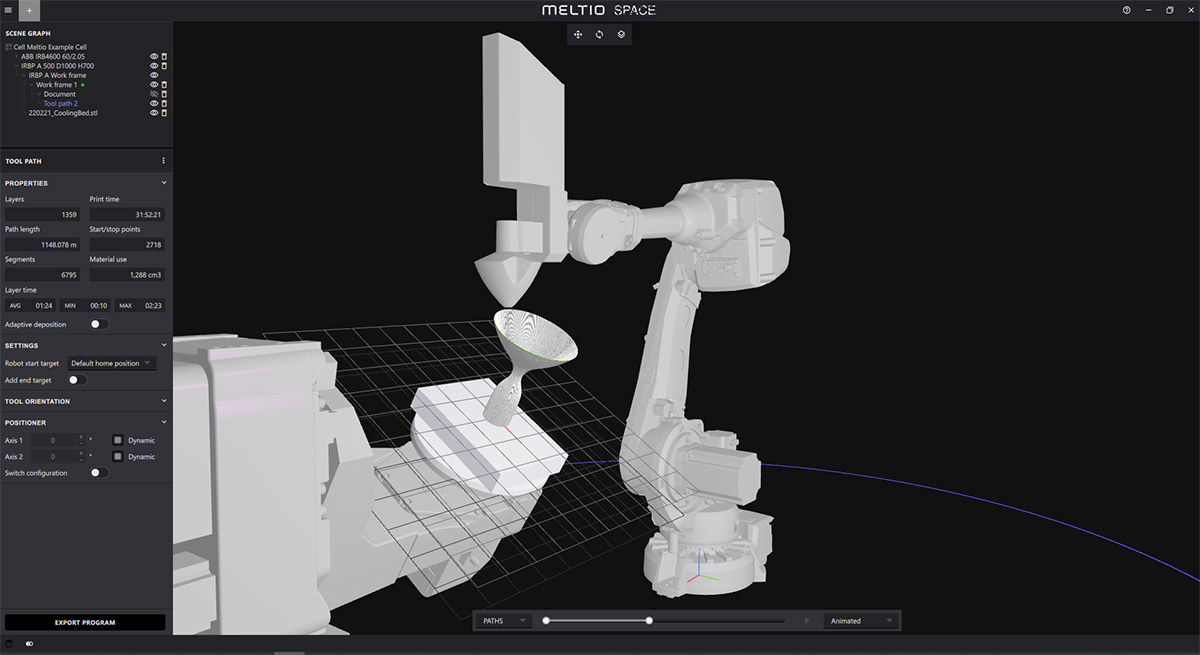

Meltio Space provides an intuitive interface for Meltio Engine Robot Integration for planar, non-planar, and variable-extrusion toolpaths, said Meltio. The robot slicer also includes two-axis workpiece positioner interpolation, kinematics simulation, collision checking, and cell configuration.

The comprehensive coordination, multi-axis toolpath generation, and enhanced design freedom provided by Meltio Space empowers users “to create intricate, customized, and highly detailed metal parts like never before,” asserted Meltio.

Additive metals manufacturing with simulation

Meltio Space is intended to remove complexity in 3D printing workflows, enhancing productivity for industrial users of all levels, said Meltio. The new software uses a virtual model of the real robot's movement. This advanced feature allows users to simulate the kinematics of the robot, ensuring precise printing, the company said.

In addition, the slicer performs collision checks with the part being printed, minimizing the risk of errors or damage during the additive manufacturing process, said Meltio.

The printing provider summarized the potential benefits of its software:

- Empower users: Meltio Space includes an easy-to-use interface and comprehensive features for popular robotic brands.

- Maximize Meltio Engine: The new slicer enhances Meltio Engine functionalities, offering optimized print profiles for different materials and applications.

- Unlock complex geometries: Meltio Space provides diverse toolpath strategies, eliminating limitations and enabling precise movements for intricate designs.

- Reduce programming time: Meltio said its technology can save time and ensure accurate printing through virtual robot movement simulation and collision checks.

- Dynamic innovation: Meltio Space includes continuous updates and development.

- Reliable support: Training programs, customer support, and resource platforms empower users to optimize the technology, Meltio said.

- Best value for money: Meltio Space combines affordability, advanced capabilities, and a user-friendly interface, maximizing investment and project outcomes, claimed the company.

Meltio works with major robotics suppliers

Prior to the launch of its next-generation software, Meltio had signed agreements with 12 major software companies to keep its technology “compatible and open.” Meltio Space includes preset and recommended material profiles and 3D printing parameters.

Unlike other software products, Meltio Space includes a built-in library and post-processors for robot arms from ABB, KUKA, FANUC, and Yaskawa at no extra cost, said Nieto.

“Meltio Space is a living platform that will provide feedback to keep improving and offers competitive software to different industrial customers of Meltio,” he said.

Meltio is working with sales partners such as EXBuild, Snowbird Technologies, and India-based IRTI Robotics. Its customers include the U.S. Navy and the U.S. Army.

Meltio offers its additive manufacturing software as an annual subscription at a price it said is competitive, depending on the capabilities. Meltio is available for free for the first year with each sale of Meltio Engine.

The company also offers existing customers to access Meltio Space free of charge for the first year if it is associated with the purchase of training through a sales channel or reseller.

Article topics

Email Sign Up