Seurat Technologies today announced a $99 million Series C round. The Wilmington, Mass.-based company said it plans to deploy its 3D metal printing factories at or near customer sites around the world. By printing parts closer to where they are needed, Seurat said its technology can help reshore supply chains and reduce emissions from transportation and global logistics.

“Our mission is to create a green manufacturing industry,” stated James DeMuth, co-founder and CEO of Seurat. “With our additive manufacturing technology, our print factories will provide our customers with clean manufacturing that can compete with the volumes, quality, and price points of traditional manufacturing.”

“This new funding will enable Seurat to unlock our next phase of growth, deploy our new machines, and scale our factory capacity to meet current demands,” he added in a release.

Metal additive manufacturing to aid sustainability

Manufacturing is one of the largest contributors to greenhouse gas emissions, responsible for 31% of emissions in the U.S., according to the Environmental Protection Agency. Current manufacturing processes take too long, prevent innovation, contribute to climate change, stretch supply chains, and offshore jobs, noted Seurat Technologies.

However, the Biden administration’s investments in green manufacturing and $6 billion commitment to cutting industrial emissions have increased attention to sustainability, said the company. Seurat claimed that it is “reinventing and reshoring manufacturing” with its Area Printing technology.

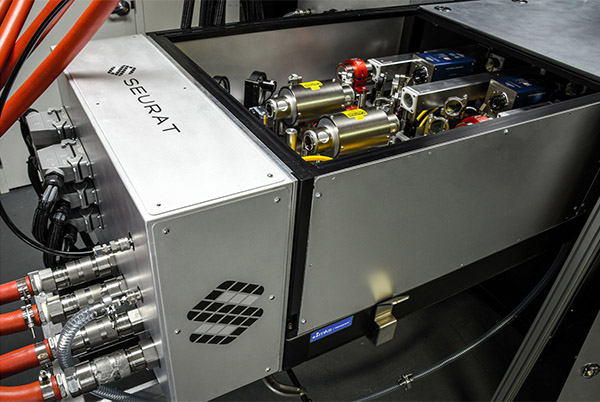

Developed at Lawrence Livermore National Laboratory, the metal 3D printing technology “delivers high-precision, high-volume, decarbonized manufacturing,” said Seurat. The company asserted that it is 100% powered by green energy and has the potential to directly mitigate as much as 100 million tons of carbon dioxide by 2030.

“By decoupling resolution and speed, Seurat is creating a scalable process that can compete with traditional manufacturing in every way,” it said. The company noted that it has nearly 130 patents and 145 trademarks granted and pending.

Seurat pilot factory already has customers

Seurat Technologies said its pilot factory in the Greater Boston area will have the capacity to produce more than 25 tons of metal parts annually. It is already oversubscribed, said the company.

Seurat has commitments to develop 59 tons of additively manufactured metal components for Siemens Energy turbines over a six-year period for parts meeting its material qualification requirements.

In all, Seurat has letters of intent from six customers totaling 4,000 tons of material and over $750 million in projected revenue over the next several years. “This business growth showcases the demand for change in the status quo of manufacturing,” said the company.

Major companies among the investors

NVentures, the venture capital arm of NVIDIA, and Capricon's Technology Impact Fund, which focuses on climate solutions, led Seurat Technologies' Series C funding.

“Accelerated computing is unlocking new capabilities within the manufacturing industry, while creating a path toward sustainability,” said Mohamed “Sid” Siddeek, corporate vice president and head of NVentures. “Seurat’s green approach to manufacturing will help transform industry standards.”

“Seurat’s potential to disrupt and decarbonize the traditional metal parts manufacturing industry is tremendous,” added Ion Yadigaroglu, a partner at Capricorn.

“We have been impressed from the early days of the company by James and his team’s technical expertise and acumen to build a highly scalable business, with applicability across numerous industries,” he said. “We are excited to participate in this round of funding, which will enable the company to ramp up production capabilities at greater scale and ultimately grow its client base.”

Other participants included previous investors True Ventures, SIP Global Partners, Porsche Automobil Holding SE, Denso Global, General Motors Ventures, Maniv Mobility LP, and Xerox Ventures. New investors included Honda Motor and Cubit Capital, among others.

“Seurat has an innovative concept and technologies for metal additive manufacturing, and Honda has high expectations for their future potential,” said Manabu Ozawa, managing executive officer of Honda Motor Co. “The metal additive manufacturing technology will enable the enhancement of the value of products through innovative design, and as Honda strives to create the joy and freedom of mobility, we envision that this technology will be necessary for us.”

“Honda will continue to search for, collaborate with, and invest in companies with a promising future through our global open innovation program – Honda Xcelerator Ventures,” he said.

Article topics

Email Sign Up