AI machine vision software provider Micropsi Industries recently announced a partnership with the Fraunhofer Institute for Factory Operation and Automation (IFF) to open a new use-case research laboratory in Magdeburg, Germany.

Additionally, Micropsi will demonstrate applications of its AI-based MIRAI machine vision system, including reflective disc picking and hook hanging, at ATX West in Anaheim, CA February 6-9 at booth 4566. Micropsi said U.S. companies can work with a local team during and after the show to workshop use cases for the new lab.

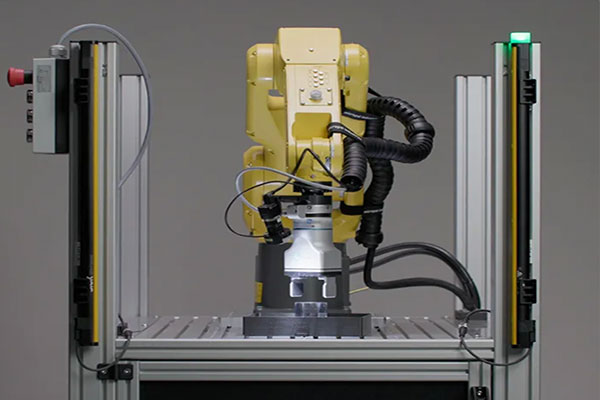

Robot arms to demonstrate MIRAI variance adaptation

Micropsi said applications such as reflective disk picking and hook hanging are too complex to automate with traditional programming. The company’s MIRAI machine vision software system allows robots to dynamically adjust to workspace changes. MIRAI enables robotic arms to be controlled in real time in direct response to sensor information taught by human demonstration.

“In our collaboration with our customers and other manufacturers worldwide, we continue to discover new applications that MIRAI can easily automate without expensive coding or knowledge of artificial intelligence,” said Gary Jackson, CEO of Micropsi Industries. “As attendees at ATX West see these applications in action, we expect they’ll recognize the unique applications that MIRAI could help them automate regardless of the variance issues that have kept them from automating before.”

At ATX West, a FANUC LR Mate industrial robot will perform reflective disk picking demonstrations. Micropsi said the demonstration will show its MIRAI machine vision software’s ability to enable robots to adapt to environmental variances and interact with reflective surfaces and extreme lighting conditions in real time. Micropsi said hook hanging demonstrations, performed by a Universal Robots UR10e collaborative robot, will show how MIRAI can deal with the positional variances of its target object by using all degrees of freedom to meet the target in 3D space.

Application lab evaluating machine learning for tasks previously considered not automatable

At their new use-case laboratory, employees from Micropsi and Fraunhofer IFF are collaborating to conduct feasibility studies and develop customized no-code robotics products for customers.

Micropsi said employees at the lab explore and test robotic applications for the MIRAI machine vision system, including tasks previously deemed too complex to be automated. Manufacturing companies can present their specific automation challenges to the use-case lab. After the lab develops customized applications, it provides instructions that allow Micropsi’s customers to replicate the final robotic operation in their manufacturing facilities. Micropsi said customized instructions developed at the application lab will eventually be made available to a wide audience.

Gary Jackson, CEO of Micropsi Industries:

“The partnership with Fraunhofer IFF opens up new possibilities for automation in applications previously considered not automatable.”

While the use-case lab is located in Germany, Micropsi said U.S. companies are invited to discuss their automation challenges with its U.S. team to determine if the MIRAI machine vision system might be an appropriate solution for their task. If deemed a fit, Micropsi’s customers can submit their potential application at the use-case lab, who will work with them to create videos, results, guidelines, and suggestions for hardware requirements.

Micropsi and Fraunhofer IFF also announced the completion of their first project: insertion of a dual in-line memory module (DIMM) by a FANUC LR 10 robot augmented by Micropsi’s MIRAI machine vision system. Micropsi said DIMM insertion is a complex task because the robot is expected to precisely insert modules into delicate slots on a motherboard, which varies in its position in the workspace.

Article topics

Email Sign Up