Editors’ Picks

Safety systems, teaching options that make working with cobot arms easier

Yaskawa Motoman HC series features simplify cobot arm deployment and operation

Another brick in the wall: Building walls with AI-powered robotic arm platforms

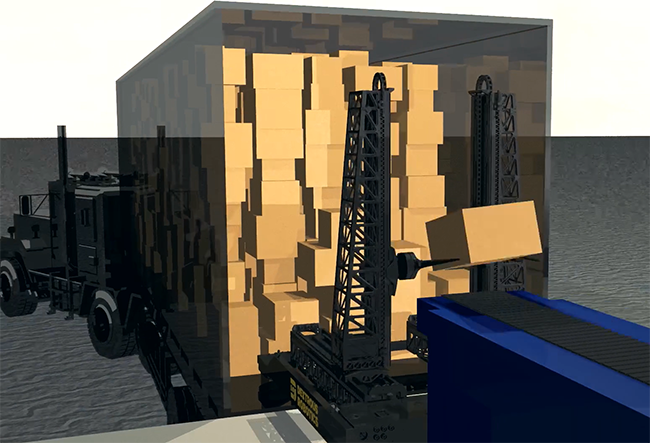

DexR truck loading system helped FedEx unlock the dock

How supervised autonomy keeps robot arms moving

Erik Nieves, CEO of Plus One Robotics, explains how purpose-built AI and...

How robotics, automation play a role in navigating economic uncertainty in 2024

HowToRobot execs lend their thoughts on industry outlooks