Editors’ Picks

Found in Robotics News & Content, with a score of 7.01

The Advanced Robotics for Manufacturing Institute (ARM) recently publicly released its Future of Work study. The study, previously issued to ARM Institute members, details how advanced technologies - chiefly robotics, automation, and AI - are changing the nature of manufacturing careers, as well as actions the institute expects will be needed to prepare the U.S. workforce for these changes. Manufacturing, and the development of technology to improve manufacturing, have been a source of American prosperity and national security for over a century. The introduction of disruptive technologies, which can address critical areas of need in manufacturing, are also changing the…

Found in Robotics News & Content, with a score of 0.31

…at Ecole Polytechnique Fédérale Lausanne (EPFL), the Swiss Federal Institute of Technology, was selected as a technology winner for his pioneering role in the invention of the Delta robot concept. Marc-Olivier Demaurex, was selected as a technology winner for his role in pioneering the Delta robot and bringing it to market. In the early 1980s, Clavel led the research team that invented the Delta robot, a type of parallel robot that consists of three arms connected to universal joints at the base designed to manipulate light and small objects at a very high speed, an industrial need at the time.…

Found in Robotics News & Content, with a score of 6.25

The Advanced Robotics for Manufacturing (ARM) Institute recently announced that three consortium member projects were selected from over 100 proposals submitted to the Office of the Secretary of Defense (OSD) Manufacturing Technology (ManTech) Organic Industrial Base (OIB) Modernization Challenge held earlier in 2024. The ARM Institute is a DoD Manufacturing Innovation Institute and a member of the Manufacturing USA Network. Providing resources for U.S. manufacturers that utilize advanced robotics and AI, the Institute connects more than 400 member organizations across industry, government and academia. OIB process took over a year before selection The OSD ManTech Program hosted representatives from five…

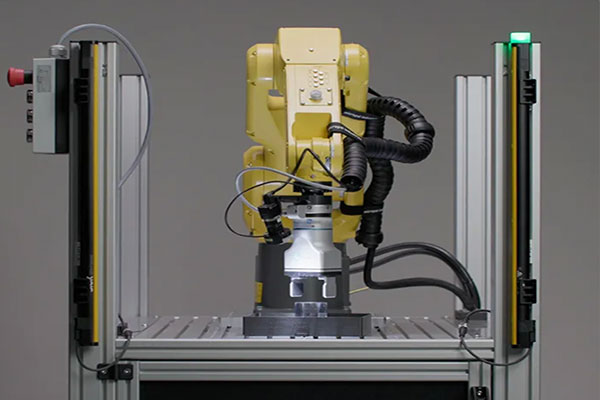

Found in Robotics News & Content, with a score of 0.93

…Micropsi Industries recently announced a partnership with the Fraunhofer Institute for Factory Operation and Automation (IFF) to open a new use-case research laboratory in Magdeburg, Germany. Additionally, Micropsi will demonstrate applications of its AI-based MIRAI machine vision system, including reflective disc picking and hook hanging, at ATX West in Anaheim, CA February 6-9 at booth 4566. Micropsi said U.S. companies can work with a local team during and after the show to workshop use cases for the new lab. Robot arms to demonstrate MIRAI variance adaptation Micropsi said applications such as reflective disk picking and hook hanging are too complex…

Found in Robotics News & Content, with a score of 18.94

The Advanced Robotics for Manufacturing (ARM) Institute recently announced a continuation of its public-private cooperative agreement with the Department of Defense (DoD) Manufacturing Technology Program. The $35.4 million agreement will continue ARM Institute’s funding as a national Manufacturing Innovation Institute for through 2028, with an option to renew the contract again for another five years. If the DoD accepts the further renewal offer, ARM Institute's total possible primary investment increases to $70.4M over 10 years. The Institute’s original agreement with the DoD provided funding through January 2023. Following a successful review by the DoD Joint Defense Manufacturing Council (JDMC) in…

Found in Robotics News & Content, with a score of 1.47

…experience in any OR globally.” OTTAVA incorporates four robotic arms into a standard size surgical table. According to the company, this unified architecture allows for an invisible design, with the robotic arms available when needed or stowed under the surgical table when not. The design removes barriers to movement and collaboration in robotic operating rooms and offers surgical teams the freedom and flexibility to adapt to clinical workflows and individualized patient needs. The system's “twin motion” feature – unified movement of the table and the robotic arms – is designed to allow surgical teams to address important clinical needs during…

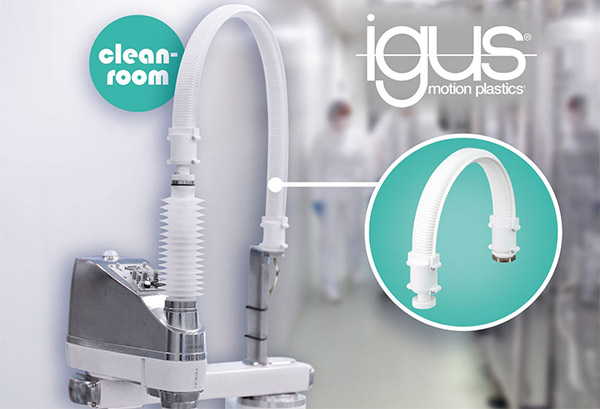

Found in Robotics News & Content, with a score of 0.46

…and hoses in an arc from the robot’s vertical arm to the end effector. Its separable upper and lower shells can be combined to form a closed, dust-proof, water-resistant tube. This ensures that particles from the cables and hoses do not get into the surrounding air from the inside – even during the wildest movements. “To reduce stress on the cables and increase their durability, we have provided a rotating mount for the connections to the fixed and moving ends of the energy supply system,” says Meyer. “That is what is special about the energy supply system. At the same…

Found in Robotics News & Content, with a score of 10.37

The Advanced Robotics for Manufacturing, or ARM, Institute last week said that it has evaluated and selected seven more training programs to endorse. The ARM Endorsement Program is a thorough evaluation process intended to identify the organizations that most effectively prepare students for careers in manufacturing working with robots. “Millions of manufacturing jobs may go unfilled in the coming years if we do not work to correct the manufacturing workforce gap,” said Lisa Masciantonio, chief workforce officer at the ARM Institute, in a release. “Effective training programs are critical to course-correcting, engaging the next generation of manufacturers, and helping to…

Found in Robotics News & Content, with a score of 0.56

…and Mobile Industrial Robots), the Advanced Robotics for Manufacturing (ARM) Institute, and MIT Lincoln Lab. Other sponsors included 6K, Synagex, Quabbin Wire & Cable, Tooling U-SME, GBMP, Equinor, the Massachusetts Manufacturing Energy Collaborative, Skylitics, Hybrid CNC Parts, Spark Photonics, Mack Prototype, AB Corp, MRSI Myronic, Modern Mold and Tool, MassDevelopment, Massachusetts Life Sciences Center, and Associated Industries of Massachusetts. Organizing partners for the event included CAM, the Massachusetts Manufacturing Extension Partnership (MassMEP), FORGE, Worcester Polytechnic Institute (WPI), MassHire, and MassRobotics. The third annual Massachusetts Manufacturing Mash-Up included networking and educational opportunities. Source: CAM Mash-Up includes student activities This year's Massachusetts…

Found in Robotics News & Content, with a score of 8.33

…this week said that the Advanced Manufacturing Robotics, or ARM, Institute has awarded it funding to develop a roadmap for guidance and adoption of advanced robotics technologies. In partnership with the institute, ASTM also plans to host its 4th Specialty Workshop on Discovery & Market Analysis for Robotics in Manufacturing of Space and Hypersonic Components. The workshop will be on Oct. 4 and 5, 2023, at ASTM headquarters in West Conshohocken, Pa. Interested parties are required to register their interest in attendance. The main goals of the workshop, which the ARM Institute funded in a recent project call, are to…

Found in Robotics News & Content, with a score of 0.67

…a survey last year by Deloitte and The Manufacturing Institute, nearly 45% of manufacturing executives said they have turned down business opportunities because of a lack of workers. The study said that most workers prefer jobs in sectors such as retail, services, and technology, even as the amount viewing manufacturing as innovative has increased from 39% to 64%. If public-private partnerships present manufacturing as high-tech and invest in training, as Forbes recommended, that positive perception could spread. North America, Europe, South Korea, and Japan might not be able to compete with China in terms of the size of their labor…

Found in Robotics News & Content, with a score of 0.50

…and hoses in an arc from the robot’s vertical arm to the end effector. The company said its separable upper and lower shells can be combined to form a closed, dust-proof, water-resistant tube. This ensures that particles from the cables and hoses do not get into the surrounding air from the inside – even during the wildest movements, igus claimed. “To reduce stress on the cables and increase their durability, we have provided a rotating mount for the connections to the fixed and moving ends of the energy supply system,” explained Meyer. “That is what is special about the energy-supply…