Editors’ Picks

Found in Robotics News & Content, with a score of 5.66

…required payload. An all-in-one interface, which can enable efficient programming of both the AMR and the cobot arm. “These new AI features to MiR’s analytic software create another real-world example of our new AI offerings, with MiR Insights leveraging the latest advancements in generative AI on top its data processing capabilities,” said Ujjwal Kumar, president of Teradyne Robotics. “At the combined MiR/UR booth at Automate, attendees can get a first-hand look at these enhancements in action.” MiR to Sponsor Women Empowerment Breakfast with Teradyne Robotics and Universal Robots With Teradyne and Universal Robots, MiR is sponsoring the Automate 2024 “Empowerment…

Found in Robotics News & Content, with a score of 9.99

…robotic products increasingly more intuitive. This includes the intelligent programming paradigms found within its robot control software. For example, the new Comau Open Controller enables external PCs to seamlessly control Comau robots. This means that companies, universities and research centers can now implement proprietary motion strategies and algorithms to control the robot rather than relying on pre-configured path management sequences. Similarly, Comau’s Roboshop Next Gen is an intuitive, PC-based programming tool that allows customers to program a robot and graphically optimize its path before online deployment. Sustainability, both in terms of energy and consumption efficiency as well as general well-being,…

Found in Robotics News & Content, with a score of 12.54

…mass-production grinding due to the economic impracticality of manual programming. The system’s advanced features, including automated programming of the robot based on scanned data, customizable process parameters and automatic target recognition, make it feasible to leverage robotic technology in a wider range of mass- and specialized-production applications. “Innovation drives the advancement of automation technology for increasing industrial efficiency, improving worker and consumer well-being and achieving greater sustainability,” said Clarissa Schwendeman, director of marketing, A3. “By recognizing and rewarding innovations that play a pivotal role in shaping the future of automation, we celebrate the industry pioneers leading us toward a smarter,…

Found in Robotics News & Content, with a score of 4.86

…to program and control Stäubli robots without needing any programming expertise. They will be able to test drive Stäubli’s user-friendly SP2 plus robotic teach pendant, direct a TX2-60 robot arm through a pick-and-place process, fine-tune settings for performance and load, and even build a basic application using the VALBlocks software tool. Robots for sensitive medical and food handling environments Stäubli said it provides automation solutions for sensitive environments and aseptic production, having launched its Stericlean series in 2009. The company has since developed lines of hygienic robots for applications in industries such as food and pharmaceuticals that can help manufacturers…

Found in Robotics News & Content, with a score of 9.14

…interface enables easy system setup and provides access to the extended diagnostic functions. To allow for a quick start, programming adapters for RS232, CANopen and USB are available as accessories.

Found in Robotics News & Content, with a score of 5.57

…the 1500MX, such as software updates for life, 80GB memory, TSC-ready capability, spindle orientation, rigid tapping, coordinated rotation, conversational programming, and a TSC-ready spindle.

Found in Robotics News & Content, with a score of 11.28

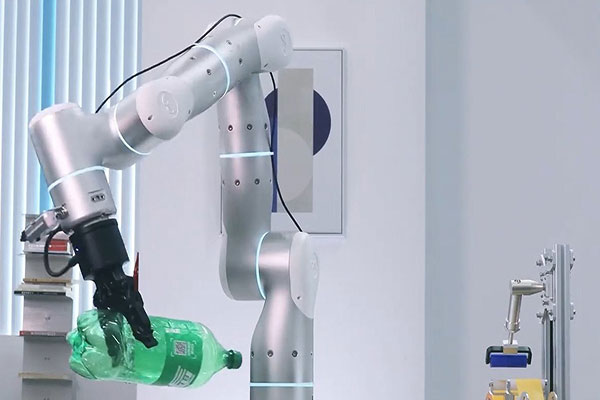

…to sort waste themselves.” Grasping randomly oriented objects without pre-programming Building on the company’s proprietary AnyGrasp machine-learning algorithm, Flexiv said Rizon is able to pick up practically any object in any orientation without pre-programming. This ability to deal with randomly-oriented objects served as the base on which Flexiv built its recycling station. Flexiv’s recycling station couples its recently-released Grav Enhanced gripper, which is capable of lifting almost any item weighing up to 5kg (11 pounds), with its new-to-market Grav Enhanced Automated Cleaning Station. The company added creating a recycling application with Rizon was a natural progression that was able to…

Found in Robotics News & Content, with a score of 9.50

…are guided by hand, either in operation or during programming. Yaskawa America Inc. Motoman Robotics Division (Yaskawa Motoman) produces a wide array of industrial robot arms. Yaskawa Motoman’s “Human-Collaborative,” or HC series of cobot arms, are designed for different kinds of interactions between robots and people. Cobots designed with people in mind From the ground up, Yaskawa designs robot arms that are applicable for as many applications as possible. All of Yaskawa’s cobots are IP-67 rated, with food-grade grease and corrosion-resistant paint as standard features. “Not all applications will need any one of those individual design elements,” said Chris Caldwell,…

Found in Robotics News & Content, with a score of 5.91

…skills. The company’s IRB 1090 education robot is designed to empower students as they learn the fundamentals of robot programming.

Found in Robotics News & Content, with a score of 9.43

…feasible to automate fully, as well as improving existing programming concepts. Benefits include ease of programming and lower computation time for planning, optimizing, and executing robot arm trajectories. For customers, this technology can help simplify the setup of common industrial applications, increasing automation potential in high-mix, low-volume scenarios. CuMotion not only allows automatic calculation of path planning for collision-free trajectories but also enables path optimization for other criteria such as speed, minimum wear, or energy efficiency. Teradyne said it expects to increase application potential and efficiency for automation customers through the combination of UR and NVIDIA technologies. MiR1200 detects pallets…

Found in Robotics News & Content, with a score of 9.17

…to connect Franka robots to MATLAB and Simulink, the programming suite and graphical block-diagram environment for Model-Based Design by MathWorks. This integration streamlines the development process, enabling researchers to bring their ideas to life with ease. By establishing a direct connection to the robot and closing the real-time loop at 1 kHz via Franka Control Interface (FCI), researchers can develop control algorithms across various modalities, visualize data and streamline the debugging and prototyping process. This real-time connectivity enhances the efficiency and effectiveness of robotics research, empowering researchers to progress at a faster pace, according to Franka Robotics. “At Franka Robotics,…

Found in Robotics News & Content, with a score of 15.76

…accessible to more people and businesses. With AI making programming easier, through lead-through and even natural language, education can shift more towards how robots can assist humans more effectively, rather than just teaching programming skills. This transition will make robots more approachable and bring them to a wider audience, leading to new job prospects while helping alleviate labor and skills shortages. “A shortage of people with the skills needed to program and support robots has long been a hurdle to the uptake of robotic automation, especially in small to medium sized manufacturing companies,” Segura added. “We will see this increasingly…