Editors’ Picks

Found in Robotics News & Content, with a score of 12.76

…in a timely and cost-effective manner. Uniform Work Robotic Sanding with Intra-stage Inspection Lead: GKN Aerospace Partners: National Institute of Aerospace Research, GrayMatter Robotics, University of Washington, EWI Description: Past ARM Institute projects on automated surface-finishing worked on path-planning, uniform finishing, and automated inspection. The project team will combine the outputs from these past projects to create an effective sanding and polishing technology that benefits multiple industries. High-Precision Adaptive Machining for High-Temperature Materials Lead: GE Research Partners: GrayMatter Robotics, FANUC Description: The project team will focus on enabling high-precision adaptive machining of complex cooling circuits in high temperature materials through…

Found in Robotics News & Content, with a score of 10.17

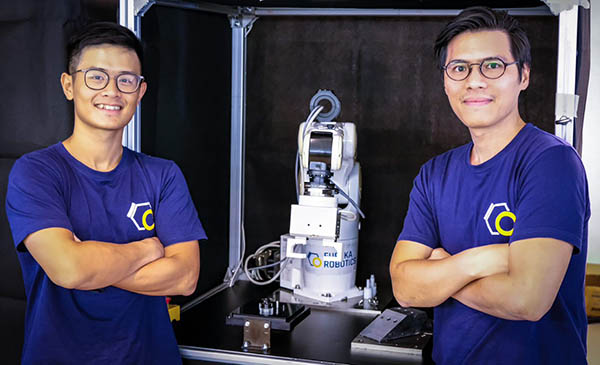

…by humans, such as assembly, fine manipulation, polishing, or sanding,” explained Pham Quang Cuong, an associate professor at NTU Singapore and co-founder of Eureka Robotics. “These tasks all share a common characteristic: the ability to maintain consistent contact with a surface.” “If our human hands are deprived of our touch sensitivity, such as when wearing a thick glove, we would find it very hard to put tiny Lego blocks together, much less assemble the tiny components of a car engine or of a camera used in our mobile phones,” said Pham, who is also the deputy director of the Robotics…

Found in Robotics News & Content, with a score of 9.87

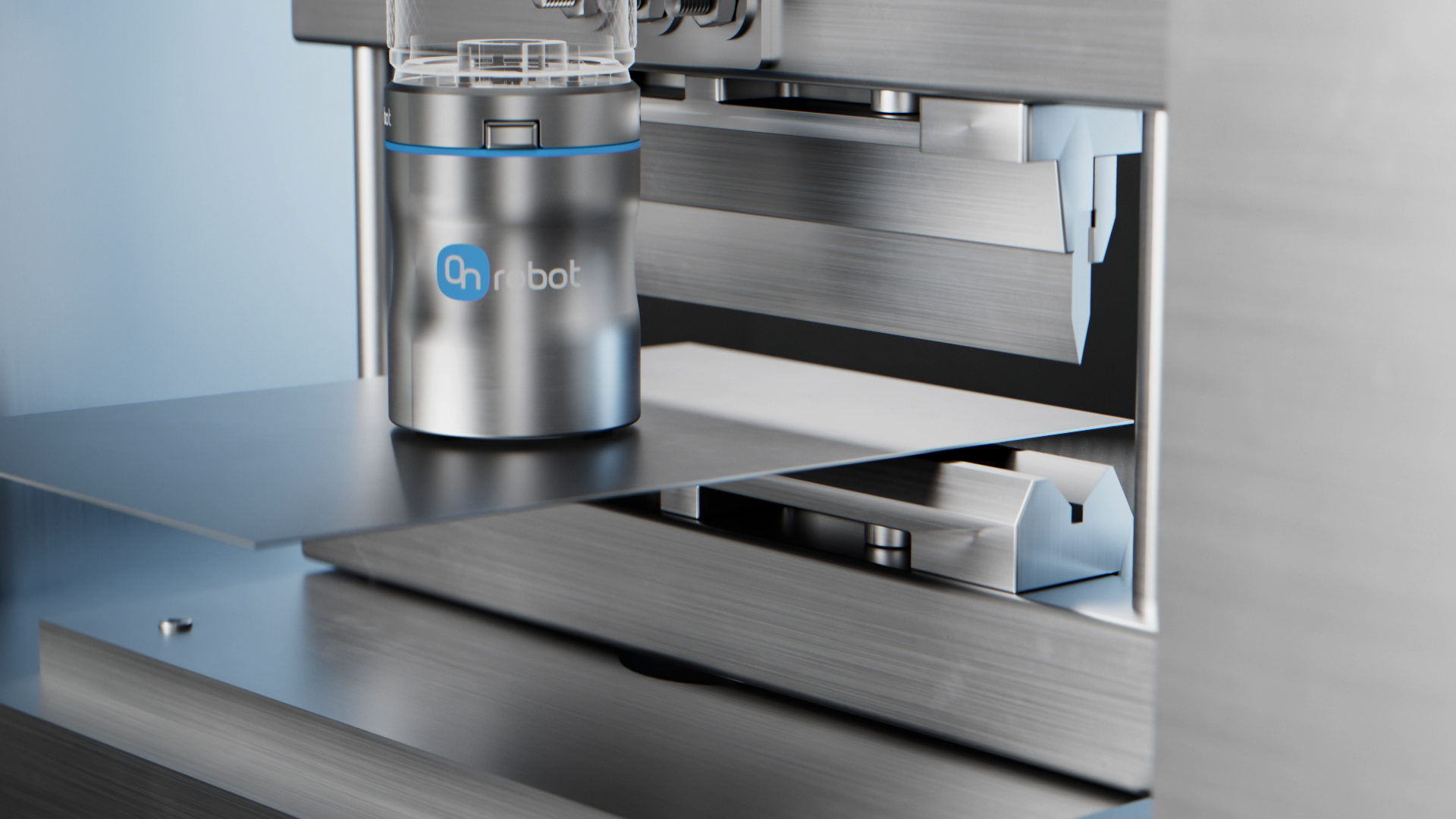

…Gecko gripping technology, force/torque sensors, “2.5D” vision, robotic screwdrivers, sanding kits, and tool changers. The company said it serves applications such as packaging, quality control, and materials handling, as well as machine tending, assembly, and surface finishing. WebLytics uses OEE standard Not only can WebLytics eliminate manual data collection for cobot end users and integrators, but it can also provide actionable insights into how well a collaborative application is performing, claimed OnRobot. The software is also designed to offer live device diagnostics, alerts, and preventive-maintenance measures to minimize costly robot cell downtime, it said. Integrating the globally recognized Overall Equipment…

Found in Robotics News & Content, with a score of 21.22

…gripping technology, force/torque sensors, a 2.5D vision, robotic screwdrivers, sanding kits, and tool changers. The company said it serves applications such as packaging, quality control, and materials handling, as well as machine tending, assembly, and surface finishing. Learn OnRobot designed for easy reference Learn OnRobot provides step-by-step guidance for tasks using the company's grippers, vision cameras, processing kits, and sensors in setups with all major cobot and light industrial robot brands, said OnRobot. Localized with support in nine languages, the platform includes an extensive library of “How To” videos and 3D simulations with detailed information on collaborative applications, including machine…

Found in Robotics News & Content, with a score of 10.41

…the best cobot for an industrial process such as sanding or assembly. When selecting a cobot, the first question to answer is what are you trying to do with the cobot? The answer to that question will help determine what attributes are most important to you. Once you have answered this question, consider the following factors, evaluated with level of importance for your application, to narrow down your options. Force-controlled or force-limited: All cobots are force-limited, but not all cobots are force-controlled. If you are solely worried about safety, force-limited is fine. However, if you want to use force control…

Found in Robotics News & Content, with a score of 17.70

…without additional sensors. An example of this would be sanding a thin composite part. In this application, it is important to control how much force is applied to avoid removing too much material and damaging the composite layers. Force-controlled robots not only offer safety, but are also useful for applications such as sanding. Source: SwRI Another example might be assembly of parts with threaded fasteners. Traditionally, this task would require precise indexing. However, with force control, the fastener position can be adjusted until it easily threads on. It is possible to get force control packages for traditional robots, but these…

Found in Robotics News & Content, with a score of 9.59

…of strategic partnerships at READY Robotics, showed a Yaskawa sanding cell and a visual inspection cell at READY's solutions center in Austin, Texas. Kel Guerin, co-founder and CIO, showed how the Unity game engine works in READY ForgeSim to simulate and program different robots and processes, such as pick-and-place and machine tending operations. This can also help with planning and training, he said. “By unlocking access to robot programming and enabling out-of-the-box control of robotics and hardware, Forge/OS 5 enables hardware OEMs like Schunk to accelerate product development and adoption, and enhance robotic applications far beyond what was possible yesterday,”…

Found in Robotics News & Content, with a score of 8.15

…gripper, the OnRobot Eyes vision system, and screwdriver and sanding tools. It also launched the 2FG7 cleanroom-ready parallel gripper. OnRobot builds MG10 magnetic gripper for smoother handling Today, OnRobot announced the MG10, a new electric magnetic gripper with programmable force features and built-in grip and part-detection features. The company said the MG10 is designed for materials handling, assembly, and machine-tending applications in manufacturing, automotive, and aerospace applications. “Standard magnetic grippers only provide simple on/off functionality,” stated OnRobot. “To adjust the force applied, users have to add rubber ‘feet’ to create space between the magnet and the part. This is a…

Found in Robotics News & Content, with a score of 18.73

…damaged parts. Traditional methods of manually removing supports and sanding, as well as dunk tanks that can warp parts, are a possible culprit. The majority of respondents in high growth markets—automotive, aerospace and defense—report that their current post-print methods are already a challenge to meeting their current additive manufacturing goals. “With PostProcess’s unique position of offering solutions across the entire market, we are able to aggregate and analyze the data with a distinct perspective,” Dean Von Bank, VP of Strategic Partnerships, says. “We’re excited to share these findings in a live webinar that will be presented on September 3rd.” PostProcess…

Found in Robotics News & Content, with a score of 6.01

…work such as heat treatments, surface finishing procedures like sanding and machining, as well as separation of the support structure from the build plate. There is also labor and time associated with preparing and cleaning up the metal powder. “Organizations need to understand the part outside of the [metal AM] system and how it needs to be processed,” says Tyson Gregory, metals application engineer at EOS Solutions. “Often that is underestimated and adds to the cost.” Before contracting for metal AM services from a third-party, it’s important to codify how the on-demand manufacturing service provider controls and monitors the build…

Found in Robotics Companies & Businesses, with a score of 37.66

…the award-winning Gecko gripping technology; and a “2.5D” vision system. OnRobot's product range also includes force/torque sensors, screwdriver and sanding kits, and tool changers. The Danish company said its end-of-arm tooling is supported by the free Learn OnRobot e-learning platform. It is designed to make it easy to deploy collaborative automation for tasks such as such as packaging, quality control, materials handling, machine tending, assembly, and surface finishing, regardless of skill level or previous robotics experience.

Found in Robotics Companies & Businesses, with a score of 46.97

Yaskawa Motoman delivers innovative robotic automation solutions for virtually every industry and robotic application, including arc welding, assembly, coating, dispensing, material cutting (laser, plasma, waterjet), material handling (diecast, machine loading, packaging, palletizing, part transfer, press tending), material removal (deburring, polishing, sanding) and spot welding.