Editors’ Picks

Found in Robotics Companies & Businesses, with a score of 70.72

Innovation is a recurring theme that accompanies almost every activity within Comau – from products to systems and from training to customer relations – and extends to spearheading a new era of automation that is open, connected, and easy to understand and use. Aided by the winning combination of advanced technological know-how and long-term experience, Comau innovation is driving the development of new products, cutting-edge technologies and a powerful concept of the factory that optimizes human and machine-driven automation. We call this HUMANufacturing.

Found in Robotics News & Content, with a score of 64.35

Comau, a global technology company, will be at Automate 2024 to present its digital-driven technology designed to accelerate deployment, increase quality and ensure sustainable productivity inside and beyond the smart factory paradigm. The company’s theme for the vision of its future is the “Power of Automation.” Automate attendees can visit Comau at Booth #4441 to learn more about the new offerings. What to expect from Comau at Automate Visitors will experience the power of perception-guided picking systems, vision-backed handling products, advanced arc welding systems and wearable robotics that help increase operator well-being during heavy and repetitive tasks. All of these…

Found in Robotics News & Content, with a score of 53.72

Comau announced late last month that it has developed a new mobile manipulation system that is being used for three European projects involving warehouse and manufacturing tasks. The Southfield, Mich.-based company has installed its Racer-5 COBOT on to its Agile 1500 autonomous guided vehicle. Each of the robots have their own batteries and can be independently controlled if needed. The company noted the system is designed “to handle individualized production within an Industry 4.0-enabled manufacturing environment.” Visual feedback for pick and place operations, as well as other tasks, is provided thanks to an integrated vision system, such as the novel…

Found in Robotics News & Content, with a score of 46.03

Industrial automation systems provider Comau recently debuted its new S-Family small hollow-wrist robot arms at Automate 2024. The trade show was held May 6-9 at the McCormick Place Convention Center in Chicago, Illinois. Attendance was free. A3 said this year’s show is the biggest yet, featuring more than 365,000 square feet of exhibit space, over 800 exhibitors, and an expected 30,000 registrants, with learning and networking opportunities. Attendees are able to see the latest in robotics, machine vision, artificial intelligence (AI), and motion control. “Comau’s new S-Family of small, high-speed robots combines efficiency and technical excellence with the features and…

Found in Robotics News & Content, with a score of 46.01

Comau and Seabery have joined forces to create an educational training program for students and workers that allows them to practice the skills needed to become proficient and certified robotic welders. The training was designed to help fulfill the global demand for expert welding professionals, the companies said. Successful completion of the course leads to the acquisition of Comau’s Robotics Welding License. Industry 4.0 automation is increasing the level of skills required by welding professionals, yet robotic welding training is seldom offered at traditional welding training institutions or vocational training centers, the companies argued. Furthermore, a standardized robotic welding training…

Found in Robotics News & Content, with a score of 43.90

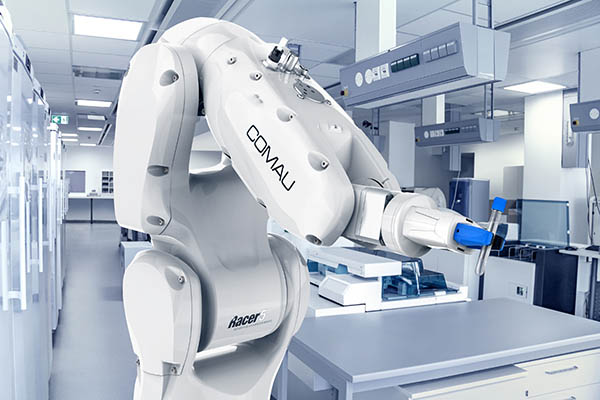

Comau has unveiled its new six-axis articulated robot, the Racer-5SE. The Grugliasco, Italy-based company said the robot was designed for the pharmaceutical, health, beauty, food, and beverage electronic industries. The robot features a protective water, heat, and grease-resistant coating, and has IP67 certification, as well as high-grade ISO 5 Cleanroom classification (ISO 14644-1). It also has protection from chemical agents, according to Comau. Further benefits of the dedicated robot include reduced operator risk when working with potentially harmful chemicals and substances, as well as increased productivity, traceability, and quality, the company claimed. Racer-5 SE addresses the specific need for speed,…

Found in Robotics News & Content, with a score of 42.22

Comau LLC last week said that it has added the N-220-2.7 robot arm to its product portfolio. The Stellantis NV unit makes the robot with its fully automated production line in its Turin Innovation Center of Advanced Robotics in Italy. “This next-generation robot, which strengthens our product portfolio, generates clear customer advantages thanks to its innovative design and state-of-the-art advanced robotics technology,” stated Nicole Clement, chief marketing officer of Comau. “[It thus allows] us to better target new, high-growth industry segments beyond traditional manufacturing, with the aim of enhancing cost-effective automation for businesses of all sizes.” Comau provides industrial automation…

Found in Robotics News & Content, with a score of 41.91

Industrial automation providers Rockwell Automation Inc. and Comau today announced today that they are collaborating on unified robot controls. The companies said their partnership will give manufacturers worldwide the tools to ease integration and deployment, as well as maximize efficiencies. “Industrial companies are looking for efficient ways to integrate robotics into their operations for process optimization and agility,” stated Blake Moret, chairman and CEO of Rockwell Automation. “Rockwell Automation’s collaboration with Comau will simplify programming and lifecycle management, accelerating time to value for our customers.” Comau said it has more than 45 years of experience in helping manufacturers of all…

Found in Robotics News & Content, with a score of 41.66

Industrial automation systems provider Comau recently introduced its new OnePicker machine vision system at Automate 2024. The trade show was held May 6-9 at the McCormick Place Convention Center in Chicago, Illinois. Attendance was free. A3 said this year’s show is the biggest yet, featuring more than 365,000 square feet of exhibit space, over 800 exhibitors, and an expected 30,000 registrants, with learning and networking opportunities. Attendees are able to see the latest in robotics, machine vision, artificial intelligence (AI), and motion control. “MI.RA/OnePicker is a result of our continued efforts to make complex technology more accessible and effective for…

Found in Robotics News & Content, with a score of 39.94

Comau SpA this week said it has built an automated welding system for Beijing Foton Daimler Automotive Co., a joint venture between Daimler Trucks AG and Chinese truck manufacturer Foton Motor. It is supporting Foton Daimler's first localized heavy-duty truck for the Chinese market, the Actros, which is based on the Mercedes-Benz global platform and uses Daimler’s truck technology. “We are honored to have been selected by Foton Daimler to work on this milestone which paves the way to localizing its first heavy-duty truck. Daimler is a global leader in the automotive industry, not only because of its large volume…

Found in Robotics News & Content, with a score of 38.47

Comau started offering industrial automation solutions over 50 years ago for many of the world’s biggest car manufacturers. As automation technology has changed over the years, so has its reach. Today, Comau is applying its field-proven experience and process expertise to meet the rising demand for automation in diversified industries such as warehousing and logistics, food and beverages, pharmaceuticals, renewable energy and other sectors looking to increase quality and efficiency with tailored automation solutions. The global technology company has returned to Automate 2024 in Chicago to showcase its portfolio of sustainable, advanced automation robotic offerings that drive the “Power of…

Found in Robotics News & Content, with a score of 29.08

CHICAGO – Global technology company Comau made a big splash during Automate 2024 in Chicago. The company’s theme during the show was “The Power of Automation” and its presence at McCormick Place during North America’s largest automation conference carried that weight. Comau released a new family of robots, including a specific nod to its red robot heritage during the show. Tim Culverhouse, Editorial Director of Robotics 24/7, had a chance to discuss these recent innovations with Comau CEO Pietro Gorlier at Automate. Follow their discussion with the audio transcription below and get a tour of the Comau booth during Automate…