FORTNA, an automation and software company for the full logistics value chain, announced the launch of FORTNA OptiSweep at MODEX 2024.

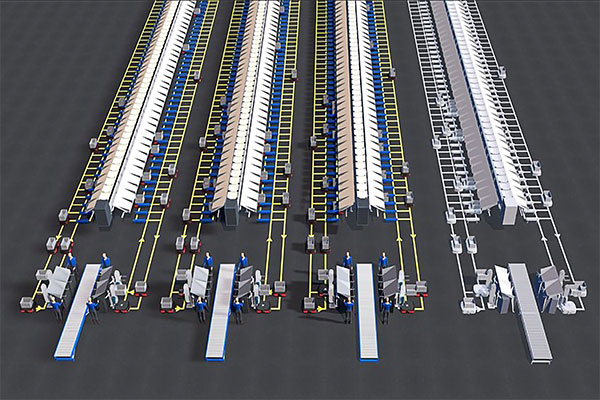

OptiSweep is a robotic offering to automate the consolidation and transportation of small orders away from sortation systems in high-volume Ecommerce and sortation distribution centers. It automates what is typically a labor-intensive process by using Geek+ robots to collect orders from sorter divert locations and bring them to specially designed goods-to-person locations to deposit orders for bulk consolidation and outbound processes.

OptiSweep details and integration options

FORTNA WCS software and its proprietary algorithms orchestrate the workflow, managing the mobile robots and communicating with the sorter and consolidation stations to maximize efficiency and balance product flow.

FORTNA OptiSweep brings a flexible robotic technology to the sorter close-out process, replacing both manual operations and legacy technologies such as the bombay sorter. Traditionally, high-volume distribution centers use large linear and loop sorters to organize packages into categories, diverting them down appropriate chutes into destination-specific bags.

These processes often have workers assigned to monitor specific destinations, physically remove items and walk them to a consolidation station for downstream processes. The FORTNA OptiSweep significantly reduces these labor requirements and provides ergonomic improvements, according to the company. It eliminates the need for workers to bend and reach into bags to move items and substantially cuts the distance and time spent walking in the warehouse.

“Labor challenges are ubiquitous across supply chains, and this post-sorting process is a prime example, marked by frequent over- or understaffing,” stated Rob McKeel, CEO, FORTNA. “OptiSweep exhibits how FORTNA is merging robotic proficiency with unmatched design and implementation capabilities to effectively address issues related to labor dependency, variable throughput demands, capacity constraints and more.”

OptiSweep integrates with sorter systems and can match a range of throughput requirements, offering processing flexibility from 4,000 to more than 34,000 pieces per hour, according to FORTNA. This throughput does not come at the price of reliability, as it also minimizes the recirculation rate in high-volume distribution centers. By mitigating the need for excess labor to accommodate demand fluctuations, OptiSweep enables businesses to maintain prolonged runtime without disruption, scale effectively and optimize facility-wide efficiency.

Article topics

Email Sign Up