MESH Automation Inc. will be displaying a version of its MiniMAC Grind Deburring cell at the International Manufacturing Technology Show, or IMTS, next month. The show is held every year at McCormick Place in Chicago. This year’s show will run from Sept. 12 to 17.

MESH Automation’s technology will be featured as part of ABB Robotics' booth, which will be located in North Building Level 3, booth No. 236520.

The Dawsonsville, Ga.-based company is an ABB Robotics Value Provider that provides a standard line of pre-engineered robotic function modules and custom automation equipment for a variety of industries and applications.

“We at MESH are excited about being part of IMTS 2022,” stated the company. “And we are particularly pleased to be a part of the ABB Robotics booth where our MiniMAC grinding cell will show you how accurate, how fast, and how consistent robots can be when deburring an aluminum part!”

How the cell operates

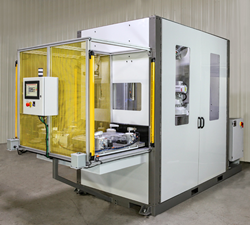

MESH Automation said its cell features an ABB IRB 2600 robot and a multiple-purpose end-of-arm tool (EOAT) mounted to the robot. The deburring and pre-machining system automatically removes excess material from die-cast aluminum parts.

The parts arrive from the casting deck, are inspected, and loaded into one of the two fixtured shuttles in the MiniMAC, the robot and tool remove the unwanted materials from each part and the finished part is returned to the operator complete.

Other features of the MiniMAC Grind System, include choices in robot model, part presentation techniques, and tooling used to remove excess materials. Each MiniMAC cell and the larger MAC and MegaMAC cells offer an array of pre-engineered productivity-improving benefits to the high and medium volume producers of cast and machined parts.

High levels of overall equipment efficiency and machine availability offered by the MAC productivity platforms provide consistent quality and cycle times in a competitive and compact package.

The booth will also include demonstrations of the latest robot and cobot technologies in a variety of industrial and non-industrial applications.

The MESH family of MAC cells are designed and proven to lower labor costs, lower ergonomic claims and offer consistent throughput to ease production planning needs, the company argues.

More about IMTS

IMTS is put on each year by The Association of Manufacturing Technology (AMT). The show has been held since 1927, according to a report by Modern Machine Shop and was first called the National Machine Tool Builders' Exposition. In the 95 years since, the trade show has certainly grown. Event organizers estimate that more than 15,000 new machine technologies will be on display at the show this year

New to this year's show is IMTS Preview Days, a complimentary online series that was designed to help IMTS attendees better understand the technologies that will be on display at the show and how to move around the venue.

“In each episode, you will gain more knowledge of the technologies displayed at IMTS, learn how to navigate your time for the best experience, and hear from an industry leader who will share where the industry is heading, discuss what role their company plays in the our future, and preview what they are brining to IMTS,” according to AMT's website.

Article topics

Email Sign Up