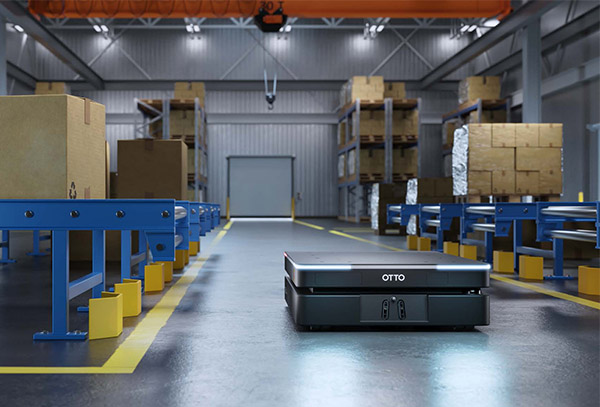

OTTO Motors today announced the OTTO 1200, which it claimed is the highest-performing, heavy-duty mobile robot for compact environments. It can safely move payloads of up to 1,200 kg (2,650 lb.), said the Kitchener, Ontario-based company.

The autonomous mobile robot (AMR) is equipped with patented adaptive fieldset technology to quickly and safely maneuver around people in narrow spaces, claimed OTTO Motors. The company said it delivers the same reliability, productivity, and durability as its other products, now in a compact package.

“Nearly a decade ago, OTTO Motors introduced the first heavy-class AMR for material handling,” stated Matt Rendall, co-founder and CEO of OTTO Motors. “Today, we’re proud to expand the capabilities of this category by unlocking countless new applications within tight areas of manufacturing environments.”

“Working closely with our customers on hundreds of deployments worldwide, we discovered an opportunity to deliver high throughput in narrow spaces without sacrificing heavy payload capabilities,” he added. “OTTO 1200 adds a compact, heavy-duty platform to our existing fleet of AMRs, enabling manufacturers to address a diverse range of material handling needs.”

Assessing the OTTO 1200

OTTO Motors replied to the following questions from Robotics 24/7 about its new AMR's capabilities:

What types of facilities or goods can most use the new OTTO 1200?

OTTO 1200 is suited for all types of manufacturing facilities, but its narrow width makes it an ideal choice for space-constrained facilities. Manufacturers building greenfield facilities can have narrow aisles when designing for OTTO 1200, saving valuable real estate.

For brownfield facilities that are already tight and crowded, OTTO 1200 still maximizes productivity. It can even help those manufacturers convert one way aisles into two-way aisles.

OTTO 1200 would also be a great fit where human and robot interaction is high. It is designed to deliver performance and safety, so manufacturers can expect to meet their throughput targets while ensuring that their people are safe.

What were some of the technical challenges of developing this robot? How does the adaptive fieldset technology allow for both safety and speed?

With the creation of any new AMR, the dynamic characterization of the system is some of the most challenging, and most essential work to be done. OTTO Motors prides itself on the due diligence paid to the understanding of how the vehicle behaves within the facility, and the generation of fieldsets that ensure the vehicle will avoid obstacles and, in the worst case, stop safely.

An AMR's fieldset is the set of programmed parameters within the lidar system that outline safe stopping regions for the robot. In a facility, the AMR gauges its size by the dimensions of its fieldsets rather than its physical dimensions and uses that perceived width to decide whether it can maneuver in an aisle or not.

If the robot identifies an object entering its fieldset, our comprehensive safety tests ensure the robot comes to a controlled, safe stop.

OTTO 1200 uses patented adaptive fieldset technology to optimize its average speed, without compromising on safety. Adaptive fieldsets work like adaptive headlights on a performance car.

The fieldsets shift and extend out in the direction the robot is turning so that the robot gets improved visibility in the direction of travel and doesn’t trigger stops based on objects the robot is actively turning away from. The improved visibility allows the OTTO 1200 to prevent unnecessary stops or slowdowns at intersections and around people, obstacles, and turns, ensuring sustained productivity and a higher average speed.

Did OTTO have to change the charging infrastructure for its new AMR, or are the power enhancements purely onboard?

The OTTO 1200 takes 30 minutes to charge from 10% to 90%. The recently launched OTTO 600 and the new 1200 both utilize an updated charge contact configuration, which customers may appreciate as quite similar to AGV deployments.

They also use the same battery, so facility space is maximized by only needing one automatic charger location for both vehicle types. This, combined with the high speed of charge, optimizes the entire charging experience for end users.

What feedback did you get from existing or trial customers while developing this system?

Customers have been consistent with their feedback that they loved the heavy payload and advanced navigation capabilities of OTTO 1500, but they wanted to have it in a smaller vehicle size.

OTTO 1200 combines the heavy payload capabilities and navigation in a compact package, which makes material movement in existing facilities seamless. With its smaller size, OTTO 1200 can fulfill that need.

Based on the IP54 rating, do you anticipate OTTO 1200 being used in different environments than your other AMRs?

OTTO 1200 and OTTO 600 are designed to IP54 rating, but they still work in the same environments as OTTO Lifter, OTTO 100, and OTTO 1500. None of the AMRs are capable of going outside, as IP54 only protects against limited dust and water, not the large amounts that they would encounter outdoors.

OTTO 600 and OTTO 1200, however, are designed to the higher IP rating, enabling them to go into dirtier facilities or facilities where there may be increased splashes of water.

OTTO Motors said its new AMR “seamlessly collaborates with other OTTO AMRs, enabling manufacturers to unlock facility-scale material handling automation.” Do you have or anticipate a lot of mixed fleets?

Absolutely. We've seen customers deploying mixed fleets for a while now, and we anticipate this trend will grow as organizations expand their fleets. Over time, we've been continually improving our software to provide even better support for larger, multi-model fleets.

In our latest software release, Version 2.28, we released a team-based traffic control feature for more effective traffic management. In mixed fleet deployments, the same set of rules do not work for all the robots in a facility.

For example, our customers may need to restrict routes for robots with overhangs to certain areas or avoid slopes for robots with sensitive payloads. Team-based Traffic Control enables users to create custom rules of the road for groups of different OTTO AMRs in the facility, resulting in reduced congestion and improving overall speed of traffic in large, heterogenous fleets.

See OTTO Motors at PACK EXPO

OTTO Motors is demonstrating the OTTO 1200 at Booth 8083 at PACK EXPO 2023 from Sept. 11 to 13 in Las Vegas.

The unit of Clearpath Robotics Inc. said it has more than 14 years of experience in automated materials handling in manufacturing and warehouse facilities. With more than 5 million hours of production experience, OTTO Motors said global brands including GE, Toyota, Ford, Amway, and Hershey trust its AMRs in mission-critical applications.

The company said it has helped customers achieve returns on investment (ROI) in as little as 11 months. Fast Company named OTTO Motors as one of the “Most Innovative Robotics Companies of 2023.”

Rockwell Automation Inc. last week announced its intention to acquire Clearpath and OTTO for a reported $600 million.

Editor's note: For more about PACK EXPO, visit Robotics 24/7's special coverage page.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up