As in North America, rail networks in Europe are in urgent need of renovation. In Germany alone, around 4,200 km (2,609.7 mi.) of track are to be renovated by 2030. Robel Rail Automation has developed a repair system that includes FANUC industrial robots.

“Our customers see a great need for fully automated, robot-assisted maintenance systems,” stated Thomas Weis, head of development at Robel Rail Automation.

This is especially true for the time-consuming and complicated repair work on points, or movable sections of track, he added. Rail network operators face increasing shortages of skilled workers such as welders.

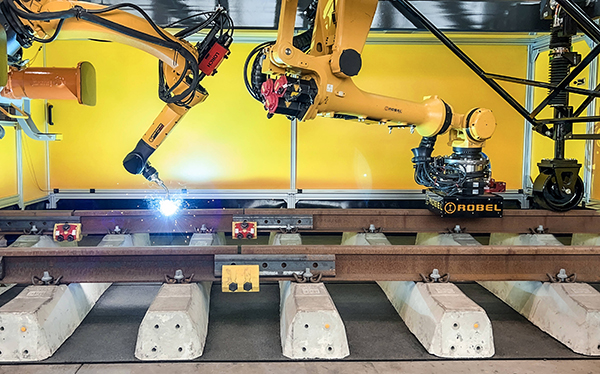

Robel Rail Automation System in testing

Robel Rail Automation is a sibling company of Robel Bahnbaumaschinen GmbH in Freilassing, Germany. Its system consists of a wagon that is pulled on rails and is equipped with two robots from FANUC.

The robots detect internal and external defects and autonomously repair them using welding, milling, and grinding processes. Robel Rail Automation is currently implementing a stationary repair system to test the individual process steps on new and used switches.

European railway networks are already running the first prototype systems, and Robel said it expects the system to be commercially available in two to three years. The Bavarian company added that its system will safely perform continuous maintenance work and help conserve resources.

In addition to robots and camera systems, the repair wagon includes integrated scanners, ultrasonic devices, and eddy-current measuring systems.

“The use of robots ensures a consistent, well-documented quality of the work,” noted Weis. “In this way, we rule out damage that is not visible to the naked eye and make measurement and process data available to our customers digitally.”

FANUC sees future for robotic maintenance

Ralf Völlinger, general manager for robotics at FANUC Europe, said he is optimistic about the future use of robots for infrastructure maintenance.

“There is a great need for modernization in both the rail and road networks,” he said. “Robots can help speed up tedious maintenance projects by taking on repetitive tasks, at least partially offsetting the growing labor shortage.”

FANUC Corp. claimed that it is the world's leading manufacturer of factory automation for CNC control systems, robots, and production machinery, including ROBODRILL, ROBOCUT and ROBOSHOT. Since 1956, the company said it has been a pioneer in the development of numerically controlled systems in the automation industry.

With more than 260 locations worldwide and over 8,000 employees, FANUC said it offers a dense network for sales, technical support, research and development, logistics, and customer care. Its U.S. office is in Rochester Hills, Mich.

Article topics

Email Sign Up