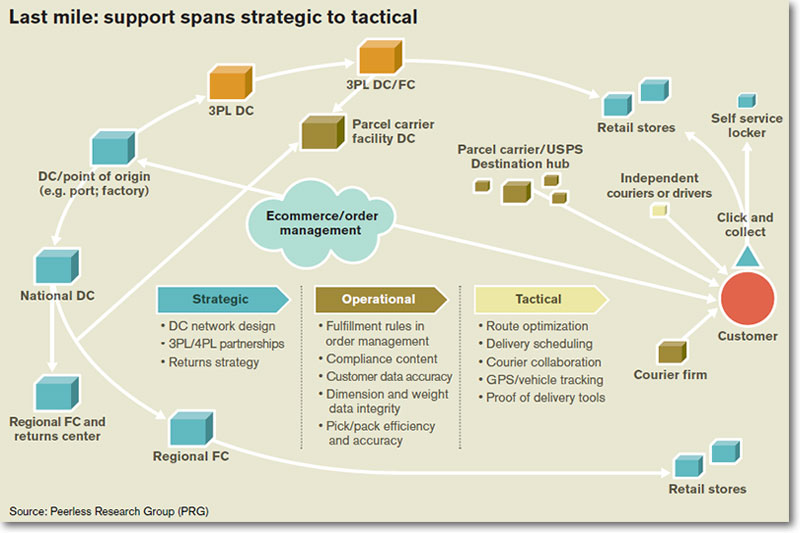

The “last mile” of e-commerce fulfillment - the processes and systems involved in making sure final delivery is efficient - is getting plenty of attention these days.

New models for handling the last mile like “click and collect” locations and added cost pressures in the form of tougher dimensional pricing from parcel carriers are forcing closer scrutiny of last-mile processes.

Adding to the attention is the activity of Amazon, which has been testing its own last-mile, same-day delivery service in San Francisco and using bike messengers in Manhattan.

Meanwhile, new services such as “Doorman” in San Francisco seek to appeal to consumers who want their e-commerce purchases collected for them at a secure location and delivered to them in one batch.

Then, there is an evolution in courier services for urban areas, in which independent drivers may begin to compete with more established local courier firms in much the same vein that Uber has shaken up taxi services in major cities.

All of these developments revolve around the final leg of the last mile. But focusing just on the last stretch of the last mile can be short sighted, according to the logistics consultants we spoke with for this article, because last-mile success calls for appropriate fulfillment rules and content at the order management and distribution center levels.

Sure, shippers need better approaches to processes like fleet scheduling and vehicle tracking, but if front-end systems for fulfillment aren’t set up with the right rules, the last mile suffers.

Having the proper network design and various fulfillment rules built into order management or ERP/WMS solutions paves the way for a smooth last mile.

Effective “final delivery” starts as far upstream as the structure of the distribution network, according to Jim Tompkins, CEO of Tompkins International. “You can go all the way back to network design and what your network should look like,” says Tompkins.

Retailers and direct-to-consumer marketplaces need to make decisions about whether they will have traditional DCs complemented by separate fulfillment centers (FCs) geared for picking and packing item-level orders, or whether they’ll have combined DCs/FCs and determine how much geography each facility should service. “These type of network design decisions will drive where your inventory will be stored, which is going to dictate quite a bit about the final delivery that needs to take place,” says Tompkins.

Last mile might involve hundreds of miles for some shippers, adds Tompkins, so “final delivery” might be the better term to describe the variation involved. For example, a manufacturer of large marine engines might have a delivery process for emergency repair parts that needs to span halfway across the globe. Additionally, a multi-channel retailer with hundreds of stores may want to leverage its physical stores as mini FCs, whereas a pure online retailer would not have those stores.

But recognizing these differences as well as the scope of the considerations, what is a common sense approach to excelling at last mile? The answer may lie in a balanced approach, spanning tactical solutions that address the final stretch of the last mile, combined with the proper attention to order fulfillment rules, compliance content, and streamlined processes further upstream in distribution.

Rules and Content

Many of the rules that drive final delivery should be established at the distributed order management (DOM) level, according to Tompkins. The DOM level is where retailers establish rules that govern when it makes sense to process orders so that they ship as efficiently as possible.

For instance, says Tompkins, if a consumer orders three items and only one is in stock at the regional DC that services a customer’s location, it might be cheaper to fill the order from a more distant DC that has all three items in stock if the order promise date can be met, and it results in one shipment rather than two or three.

“It’s about having an order management system that is truly functional for e-commerce fulfillment,” says Tompkins. “If you’re sending too many shipments to fill one order, it not only costs a fortune, it’s confusing to the customer.”

And, details about the dimensions and weights of items need to be established in back-end systems for ordering or the warehouse management system (WMS). This type of data needs to be highly accurate to ensure that systems used for shipping and carrier selection function properly and to ensure that items can be matched with appropriate-sized shipping boxes. “Today, you absolutely have to be able to understand the impact of dimensional pricing,” says Tompkins.

At SEKO Logistics, a 3PL that offers final-mile solutions, much of the success with last mile actually lies in the establishment of shipping rules and retailer/marketplace compliance details within the order fulfillment software SEKO uses on behalf of clients, says Brian Bourke, SEKO’s vice president of marketing.

For example, says Bourke, if an order comes in for a 55-inch flat screen TV from one of the client’s channels and only a certain courier can handle that size product for that location, the fulfillment system’s rules are aware of this constraint and will select the correct courier and generate the shipping documents.

Similarly, the system would be configured to follow retailer- or marketplace-specific rules on factors like label placement, or to distinguish the orders that are best shipped as part of a less-than-truckload (LTL) shipment to a store.

This type of automation of fulfillment rules and content doesn’t happen magically, notes Bourke, but instead relies on SEKO properly configuring the order fulfillment solution. “If you’re able to write in those rules on the front end, the whole process runs relatively smoothly when it’s time to execute the final mile,” says Bourke.

SEKO’s order fulfillment solution spans order management, WMS and transportation management system (TMS) functionality. SEKO offers these applications on a software-as-a-service (SaaS) basis and may integrate the software with a client’s enterprise resource planning (ERP) system or WMS to obtain order and inventory data.

Companies can do this type of rules-building on their own, says Bourke, but regardless of who does it - a 3PL/4PL that specializes in fulfillment or a company establishing its own multi-channel order fulfillment platform - it’s crucial that upfront rules building gets done.

“The principle of ‘measure twice, cut once’ very much applies to the upfront rules for last-mile fulfillment,” says Bourke. “If you can sit down and agree on what the rules need to be, and the carrier rates and tariffs are built into your solution, then last mile becomes an automated process that runs much more smoothly.”

Optimizing Delivery

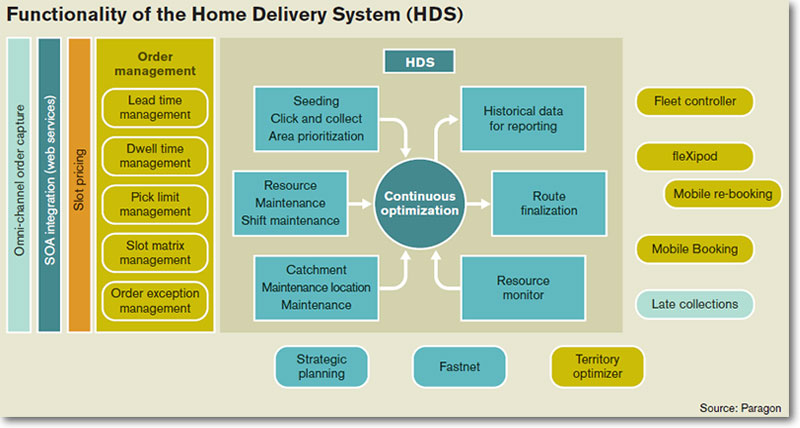

Dynamically optimizing delivery routes while tying into order management to present options to customers are functions being addressed by Paragon Software Systems and its Home Delivery System (HDS).

The solution differs from batch-based route optimization in that users can continually drop in new delivery orders and have the software optimize the best route, either in terms of fastest delivery time or the most cost-effective delivery window, says William Salter, Paragon’s president and CEO.

Batch-based fleet routing can work well for shippers like auto parts suppliers who deliver to other businesses on an almost daily basis, says Salter. In these environments, a batch optimizer can plan the next day’s deliveries after all the orders for a day have been received.

But with home delivery of items like bedding, furniture, cabinets and home appliances, the delivery requests are constantly cropping up, and customers might not be home during the day to receive goods, so they desire precise delivery options.

The HDS fits the home delivery scenario well, says Salter, because its software engine is a “continuous optimizer” that drops new requests into the pool of deliveries already in the schedule and generates options that take into account the actual constraints and resources at play, such as the road network and the number and types of delivery vehicles available.

Dynamic vehicle routing and scheduling solutions can drop new delivery requests into the current pool of deliveries and come up with a range of optimized delivery options.

“You can continually throw orders at the HDS, and it will continually optimize the routes and the schedules over the time that orders are getting fed into the system,” Salter says.

HDS also integrates with order management and outbound shipping functionality in ERP and WMS solutions. Because of ties to outbound shipping information from WMS or ERP, the HDS knows when inventory is available to ship. The integration with order management allows for optional delivery dates to be merged into a retailer’s order management process.

The system’s optimization can suggest the first or most convenient delivery window, which may cost more to execute, or other delivery windows that might fall on a later date or a different time of day, but would be the most cost efficient to carry out given the route schedule. “So quite a few of our customers will try to encourage the end customer to pick what would be regarded as the greenest, most efficient delivery window, and there might be a lower cost associated with choosing that window,” says Salter.

Paragon HDS users include Dreams, a bedding retailer using the system to schedule 6,000 home deliveries a week in the United Kingdom. Dreams delivers with its fleet of Mercedes Sprinter vans, picking up from a network of nine home delivery depots.

Dreams has integrated HDS with a Microsoft Dynamics NAV ERP system so that when a customer order is processed in the ERP system, it calculates the earliest availability date for the products and passes the data to HDS to work out the optimized delivery times to offer the customer. The delivery options are presented graphically to Dreams sales staff in red, amber and green shadings, with green being the most cost efficient delivery option.

The solution also integrates with GPS vehicle tracking units in the Sprinter vans allowing the system to monitor deliver progress. This generates a live report feed for Dreams’ Intranet to monitor the progress of deliveries.

Efficiency at All Levels

At the DC level, there needs to be a high degree of accuracy and efficiency in pick, pack and shipping processes. According to Bob Fischer, CEO of Advanced Distribution Solutions Inc. (ADSI), one way to gain efficiency is to combine packing, validation and shipping processes into one step using modular software at one station.

To this end, ADSI’s Pack-IT solution allows for a worker to scan items into a carton, which validates the correct items and quantities are in the carton, while Ship-IT software can be used at the same station to handle carrier selection and generation of shipping labels.

“Instead of having separate processes, we’ve integrated the pack and ship processes,” says Fischer. “This streamlines the workflow, while ensuring that you are shipping the right items in the right boxes to the right customers and addresses.”

Users of ADSI’s software include Legendary White Tails, an online retailer of clothes and equipment for hunters, which deployed Pack-IT and Ship-IT at its Slinger, Wis., distribution center, integrating the software with its order management system. The solution is credited with improving order accuracy to greater than 99 percent, while accommodating the high volume in the fall peak season for sales of hunting gear.

Depending how busy the DC is, up to 20 pack/ship stations use the combined solution, with each station capable of handling 60 orders per hour. The packers capture and validate each line item by product code and quantity shipped, and use ring scanners to allow for a more hands-free operation.

Pack validation software does require integration to order management, notes Fischer, so that it can alert packers if a duplicate or wrong item is scanned. “That’s an important part of solution - integrating with host systems and the order level details those systems provide,” he says.

With shipping software, it’s also necessary to establish carrier selection rules so that the people running the shipping station can have the system automatically select the best carrier for an order given factors such as dimension or weight. “You have to automate these processes through technology, or they’re not easily executable,” says Fischer.

Todd Everett, COO for Newgistics, a logistics services and e-commerce solution provider for direct-to-consumer retailers, agrees that systems at the DC level have to be ingrained with the proper rules for final delivery to work smoothly, as well as to speed returns processing.

Today, according to Everett, an online retailer can have nearly perfect order accuracy, but the rate of returns may be 20 percent or higher because many buyers purchase multiple sizes or colors of the same item, and inevitably will return the ones that don’t fit or that they don’t like. “You have to have good technology and ensure that all of the steps in your fulfillment process are being guided and monitored by those technologies,” says Everett.

Everett says many online retailers have made use of Newgistics’ “SmartLabels,” which are prepaid, preaddressed return shipping labels that can be dropped in the mail or at a U.S. post office. The labels have customizable fields that can hold data such as customer information, order number or the DC of origin, which generate useful data as labels are scanned during the returns process.

Attention to a smooth returns process is vital, Everett contends, because it will drive more business. “If the consumer doesn’t have a convenient and enjoyable returns experience, they probably aren’t going to buy from that retailer again,” he says.

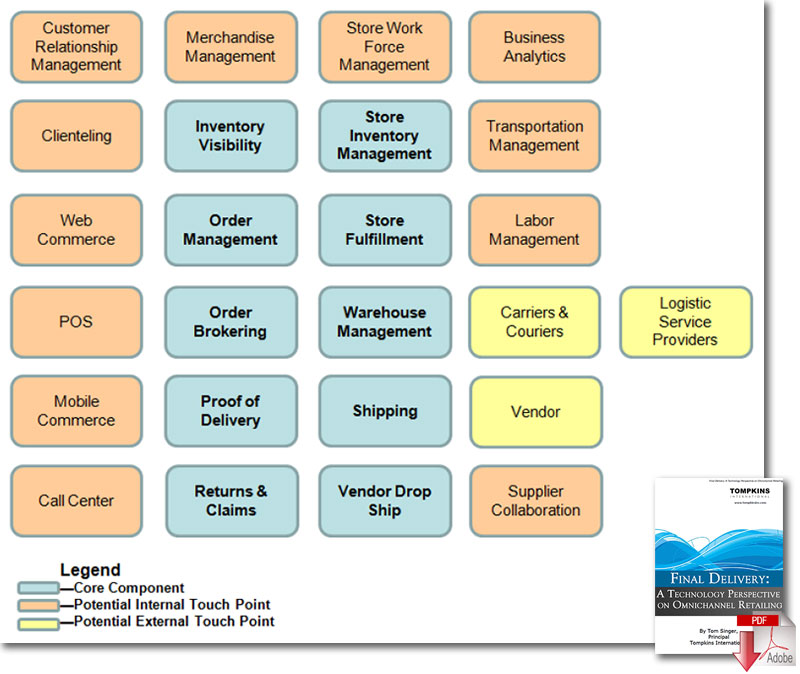

Ultimately, the toughest part about the last mile is the scope of the contributing factors. As Tompkins sees, prowess with final delivery takes strategic thinking about the fulfillment and returns network, backed up by the right structure and supporting systems at each point in the process.

Final Delivery Functional Components

The core components that may make up a final delivery solution, and potential internal and external integration touch points.

“The correct approach is to focus first on strategy, then on structure, followed up by implementing the systems you need,” Tompkins concludes.

Article topics

Email Sign Up