Editors’ Picks

Found in Robotics News & Content, with a score of 24.88

…Robotics launched its latest automatic trailer truck loading and unloading system in North America at MODEX 2024. The system features VisionNav’s newly unveiled VNST20 PRO automated guided vehicle (AGV). The trade show is being held March 11-14 at the Georgia World Congress Center in Atlanta, GA. VNST20 PRO AGV turns 180 degrees inside trailers VisionNav’s new offering combines its VNST20 autonomous forklift, a robot control system (RCS) for fleet scheduling, and 3D LiDAR for simultaneous location and mapping (SLAM) with deep learning positioning technology. The system has been designed specifically for automated loading and unloading of trailer trucks and manual…

Found in Robotics News & Content, with a score of 23.91

…for its Pixmo robotic offering for truck and container unloading. The patent-pending add-on includes a vertical lift with a conveyor belt that is attached to Pixmo between the robot and the boxes to be unloaded. The integrated Pixmo software quickly processes the various heights of the boxes in the container and then controls the conveyor of the add-on to move up and down to these positions to “meet” the robot arm as it unloads. The add-on, according to Anyware Robotics, enhances unloading efficiency, weight capability and reliability at marginal additional cost. Pixmo arm expands unloading throughput Every year an estimated…

Found in Robotics News & Content, with a score of 20.76

Container- and truck-unloading robot developer Anyware Robotics recently announced it completed the first pilot of its Pixmo robot arm, with a commercial version planned for later in 2024. Anyware also announced it will demonstrate Pixmo at MODEX 2024 in booth A11227. The trade show will be held March 11-14 in Atlanta, GA. Anyware Robotics was founded in January 2023. The company raised $5 million in seed capital in March 2023, and said it is actively negotiating another round of funding to accelerate bringing Pixmo to market. Anyware said its robot arms can autonomously unload boxes in containers and trucks more…

Found in Robotics News & Content, with a score of 20.40

Pickle Robot Co. knows that truck unloading is a major challenge for warehouse operators, from throughput and ergonomics to employee retention. It has applied artificial intelligence and robotics to solving the problem. The Cambridge, Mass.-based company this week announced $26 million in Series A funding and that its robots are already unloading tens of thousands of packages from trucks in pilot deployments. Industry veterans also joined Pickle Robot's executive team. AJ Meyer, founder and CEO of Pickle Robot, answered the following questions from Robotics 24/7: How long have the pilot implementations been going? Do you expect a lot of feedback,…

Found in Robotics Companies & Businesses, with a score of 20.15

…a broad range of controls and automated equipment, including but not limited to sorters, conveyors, and extendable loading and unloading systems. The company's subject-matter experts provide support to maintain materials handling systems for peak performance, with predictive analytics and local technicians to maximize long-term value and return on investment. MHS has a global installed base of over $5 billion for small to large distribution and fulfillment projects in a variety of industries, including e-commerce, parcel, third-party logistics, and outside integrators.

Found in Robotics News & Content, with a score of 19.08

…its AI-based Depalletization and Delayering tools for automated pallet unloading. The Bratislava, Slovakia-based company said they can increase efficiency, reliability, and safety, as well as order-fulfillment accuracy for logistics businesses. “We trained the AI algorithms on huge datasets of images to provide customers with a robust and reliable solution for any type of fully automated pallet unloading,” stated Marcel Svec, vice president of strategy and products at Photoneo. “The algorithms can recognize any type of items and boxes, including different sizes, irregular shapes caused by damage, or problematic surfaces such as varying textures, shiny and reflecting materials, black color, protruding…

Found in Robotics News & Content, with a score of 18.37

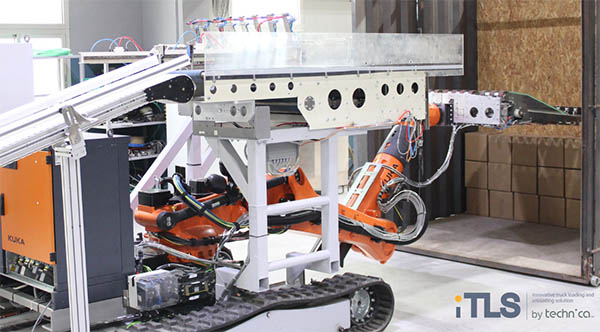

Robots for loading and unloading trucks are still emerging, and they are getting smarter. GreyOrange Inc. and Technica International this week announced a new partnership to combine Technica's iTLS technology with GreyOrange's GreyMatter fulfillment orchestration platform. The companies claimed that the combination of Technica's innovative truck loading and unloading system and the GreyMatter robot-agnostic platform will improve dock efficiency and speed. They added that their integrated offering can improve efficiency and safety, as well as enable scarce workers to focus on higher-value tasks. “Due to increasing needs for delivering goods from warehouses to retailers, introducing this new technology with the…

Found in Robotics News & Content, with a score of 17.94

…is the largest bottleneck in our supply chain, and unloading trailers is back-breaking work. TruckBot will improve safety and effectiveness for warehouses across the globe while unlocking the possibility for true fully-autonomous operations.” Mujin said it develops “machine intelligent” robot controllers that are designed as a common platform for industrial and collaborative robots specializing in logistics and other pick-and-place applications. Launched in Tokyo in 2011 with offices in China and operating in the U.S. at Mujin Corp., the company said it works with many of the world’s largest businesses to make material handling applications easier to deploy, more accurate, and…

Found in Robotics News & Content, with a score of 17.04

…Robotics showed off its new system for loading and unloading trucks. The company said the event marked the beginning of its global tour for the product. As the beginning and end of intralogistics, truck operations at loading docks can be the most time-consuming part of the process, demanding higher efficiency, stated Vivian Han, sales director for Korea at VisionNav, in a press relase. “Two key factors make the automation of truck loading and unloading difficult,” she said. “First, trucks vary in types and specifications, like a flat truck, a gull-wing container truck, and a cargo container truck. The width of…

Found in Robotics News & Content, with a score of 16.96

…mobile robot] specifically for the task of loading and unloading truck trailers, augmenting human talent,” he said. Gideon designs Trey for productive collaboration Founded in 2017, Gideon Brothers d.o.o. said it builds flexible automation to help automate material handling in complex warehouse and manufacturing operations. The company, which has offices in Zagreb, Croatia, and Dover, Del., said its AMRs use proprietary spatial artificial intelligence and 3D vision technology to orchestrate workflows of humans, robots, and other equipment, supported by real-time data. Gideon said its new trailer loading and unloading system combines its proprietary autonomy technology, user-friendly software for smart workflow…

Found in Robotics News & Content, with a score of 16.55

…Co. today announced that its pilot implementations are live, unloading tens of thousands of packages per month at customer sites in the greater Los Angeles area. The startup also said it has raised $26 million in Series A funding and added industry veterans to its leadership team as it brings its systems to market. Founded in 2018, Pickle Robot said it addresses warehouse challenges using industrial robots with artificial intelligence, computer vision, and advanced sensors. The Cambridge, Mass.-based company said it is currently focusing on applying its technology to one of the most labor-intensive, physically demanding, and highest turnover work…

Found in Robotics News & Content, with a score of 15.88

…to increase throughput HAIPORT is an automatic loading and unloading machine that can be docked with HAI ROBOTICS’ ACRs and conveyor workstations. At a HAIPORT-powered Workstation, multiple loads of totes or cartons are unloaded from the HAIPICK robots at the HAIPORT loader. They are then transferred onto conveyor belts for sorting per system orders and moved to the HAIPORT unloader, where they were fetched by robots for the next round of order processing. The collaboration between the HAIPICK robots, HAIPORT, and the conveyor allows one-stop case handling from inbound to outbound orders, said HAI Robotics. With case loading and unloading…