A new study from the University of Tennessee, Knoxville’s Global Supply Chain Institute identifies five technologies that companies should examine to ensure their long-term survival as a flood of new technologies in the past decade foretells a supply chain revolution.

The white paper looks at drones, driverless vehicles, 3-D printing, wearable technology and robotics.

It assesses the current and potential use of these technologies as well as the benefits and barriers to using them.

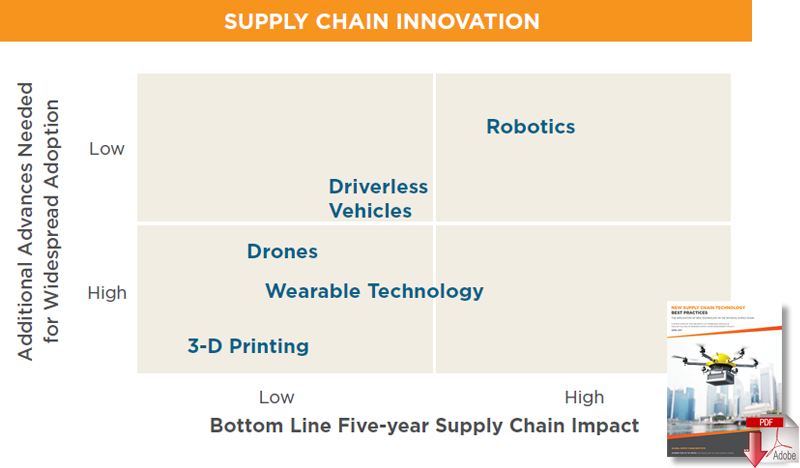

Of these technologies, the experts consider robotics to be the greatest potential disruptor over the next five years.

“Robotics have been around for more than 50 years, but they have become dramatically more dynamic in the last five,” said Paul Dittmann, executive director of the Global Supply Chain Institute and author of the paper.

“They are no longer stationary, blind, expensive and unintelligent but can work alongside people and learn as jobs change.”

Drones might not be ready for their anticipated role in last-mile delivery of consumer goods but are close to helping with less technically challenging tasks such as tracking warehouse inventories or managing trailer yard security.

Wearable technologies like smart glasses will likewise find application in the warehouse, helping workers sort, pack and inventory items as well as identifying safety hazards or the shortest path to their next pick.

Driverless vehicles have already been tested and approved in seven states and will substantially affect transportation costs once they can be caravanned or reach a port-to-port automation point.

Considered the least viable in the short term, 3-D printing is identified as having the potential to eliminate the supply chain completely if costs can be reduced and usable materials expanded.

The report notes that these physical technologies are inextricably linked to digital innovations like big data and the Internet of Things.

Real breakthroughs will require a seamless link among the physical devices and their digital and software interfaces.

“We are at a turning point in the industry where disruptive innovation is required to meet the exponentially growing customer expectations,” said Danny Halim, vice president of distribution and 3PL strategies at JDA Software.

Dittmann tapped a wide range of expert sources, including multiple large and well-known companies, service providers and technology start-ups, to author the white paper, “New Supply Chain Technology Best Practices.” It is the first in UT’s Technology in the Supply Chain series.

Kenco Logistics and JDA Software sponsored the paper.

Article topics

Email Sign Up